Originalqualität Lebenszyklus, Ersatz- und Verschleißteile

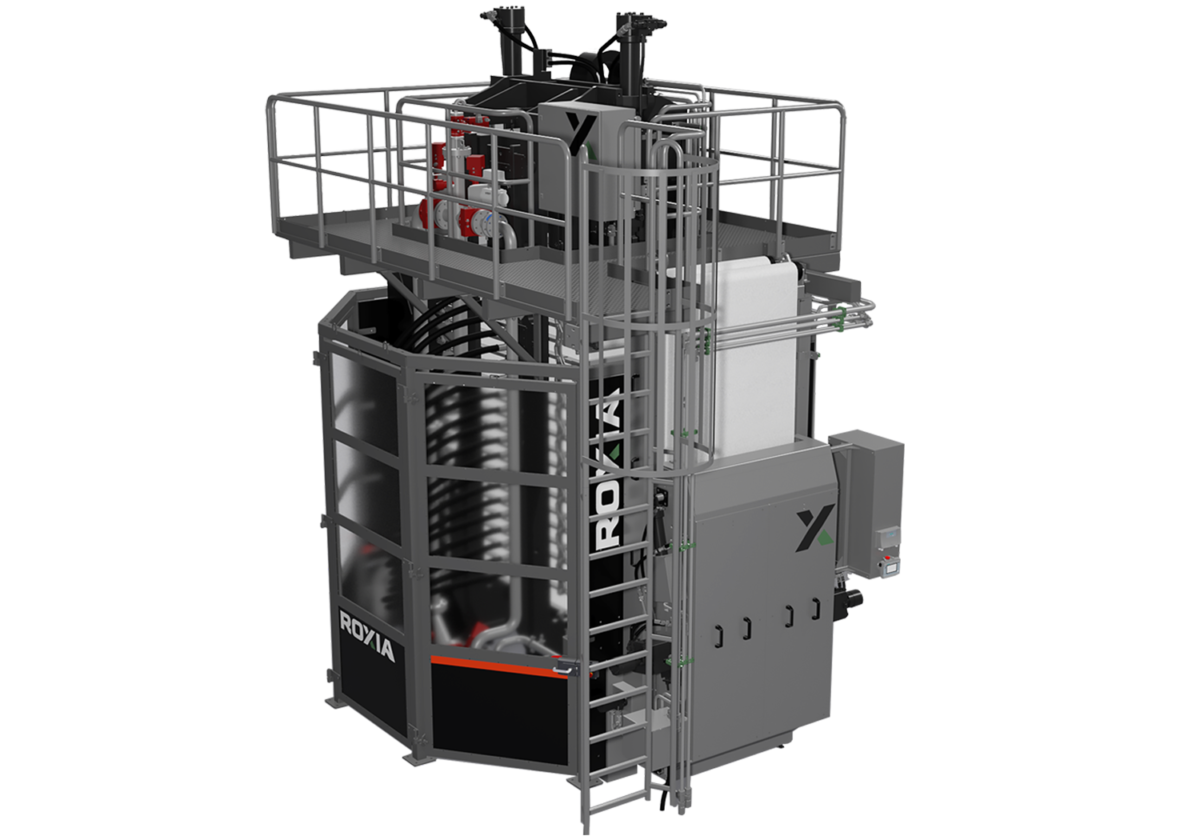

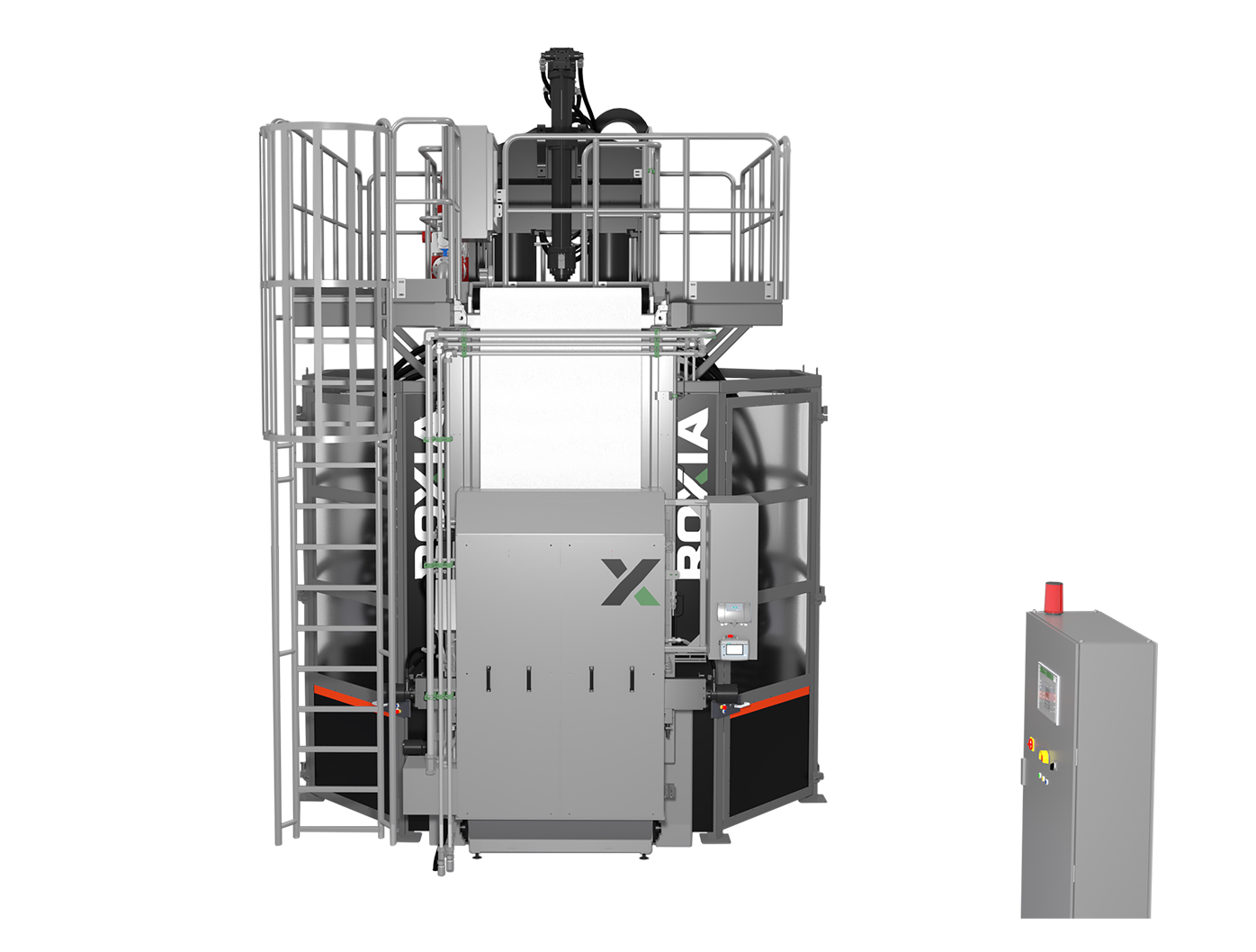

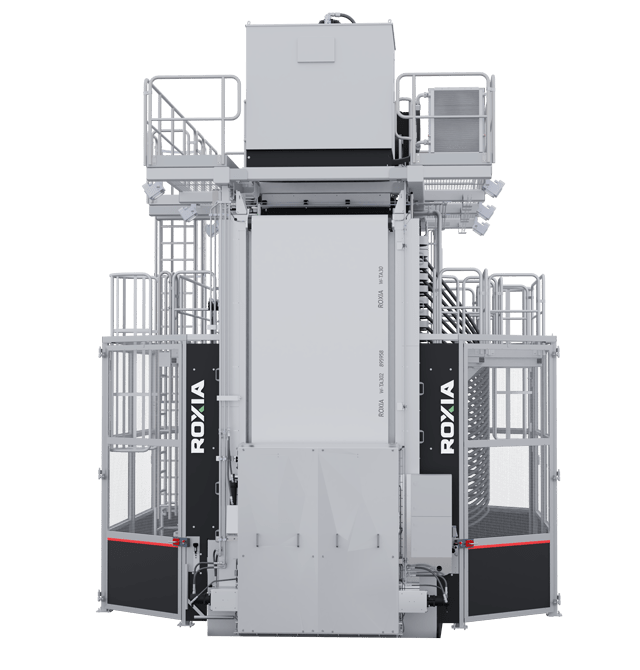

Roxia verfügt über mehr als 40 Jahre Erfahrung in der Fest-/Flüssig Trennung, Pressfilterautomaten, Kammerfilterpressen und Turmfilterpressen. Ein Team von erfahrenen Roxia-Filtrationsfachleuten erfüllt alle Anforderungen in Bezug auf Filtration und Filterservice.

Wir unterstützen Anwender von Filtrationsanlagen bestmögliche und zuverlässige Prozessergebnisse bei optimalen Betriebskosten zu erzielen. Darüber hinaus bietet Roxia über den gesamten Lebenszyklus, Ersatz- und Verschleißteile: Filtertücher, Filterplatten, Membranen, Filtergitter, Filterrollen, Filterrahmen usw.

Roxia bietet auch Service- und Wartungsdienstleistungen sowie Modernisierungen. Mit dem neuen und einzigartigem Roxia Analyse Tool, Smart Filtration, bieten wir zusätzlich die intelligente Filtrationslösung im digitalem Bereich.

Filter Ersatzteile

Filtertücher

Filtertücher für alle Filtergrößen und Anwendungen. 3 verschiedene Breiten, 10 verschiedene Luftdurchlässigkeiten und 4 verschiedene Nahttypen.

Filterplatten und -Rahmen

Für Plattengrößen von 1,6 m² und 6,0 m². Kammerhöhen: 45 mm und 60 mm. AISI 304L, AISI 316L.

Komplette Plattenpakete

Für Filterplatten von 1,6 m² und 6,0 m².

Filterollen und Abstreifer

Antriebsrollen, Spannrollen, Laufrollen und Plattenrollen mit folgenden Beschichtungen: PU, NR, EPDM und Edelstahl. Tuchabstreifer und Rollenabstreifer mit folgenden Materialien: PU, Gummi.

Membranen

Flache Membranen für Plattengrößen von 1,6 m², 2,5 m²und 6,0 m². Hohlmembranen für Plattengröße 1,6 m² . NR und EPDM.

Wannen

Plattengrößen von 2,5 m² und 6,0 m². PE.

Gitter

Verschiedene Typen und Größen für Plattengrößen von 1,6 m², 2,5 m2 und 6,0 m². PP.

Plattendichtungen

Dichtungsmaterialien:

NR und EPDM.

Schläuche

Suspensions- und Filtratschläuche . Schläuche für Wasser-/Druckluft . EPDM, NR.

Hydraulik

Ersatzteile für Hydrauliksysteme wie Schläuche, Dichtungssätze, Ventile, Zylinder.