Complete filtration support

Roxia can also provide detailed analysis of process, filtration testing, equipment selection and sizing for this and other kinds of industrial filters needed for solid-liquid separation. Get complete service through the entire filter life cycle, modernizations, refurbishments, spare parts and maintenance support.

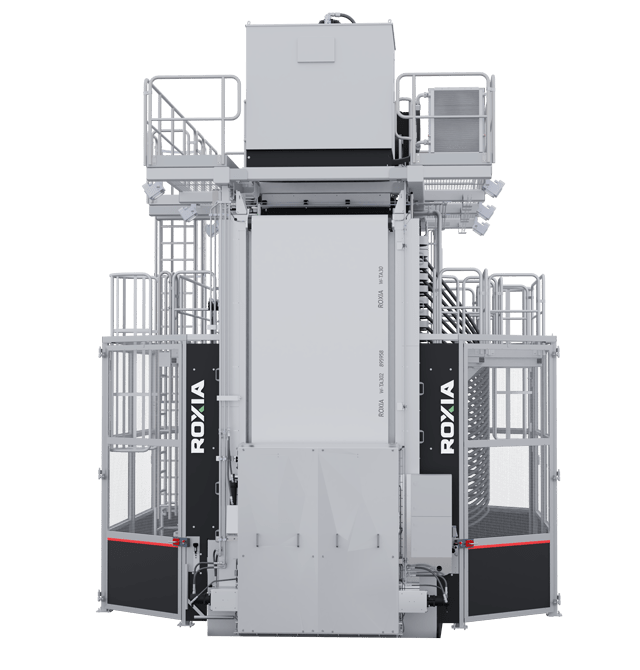

In addition to Roxia Tower Press™ filter, we also deliver complete solutions including the most important auxiliaries.