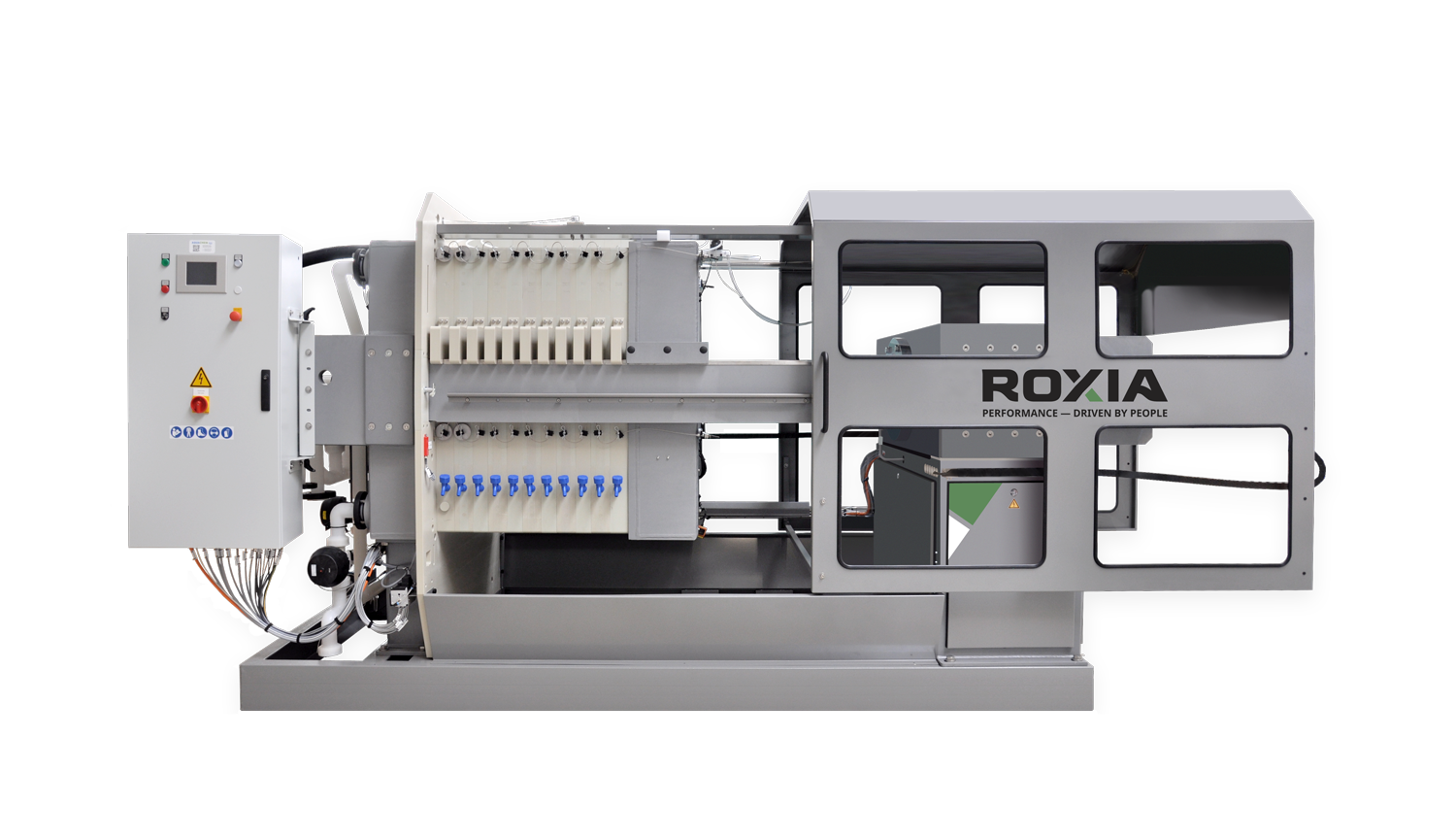

Komplette Filtrationsunterstützung

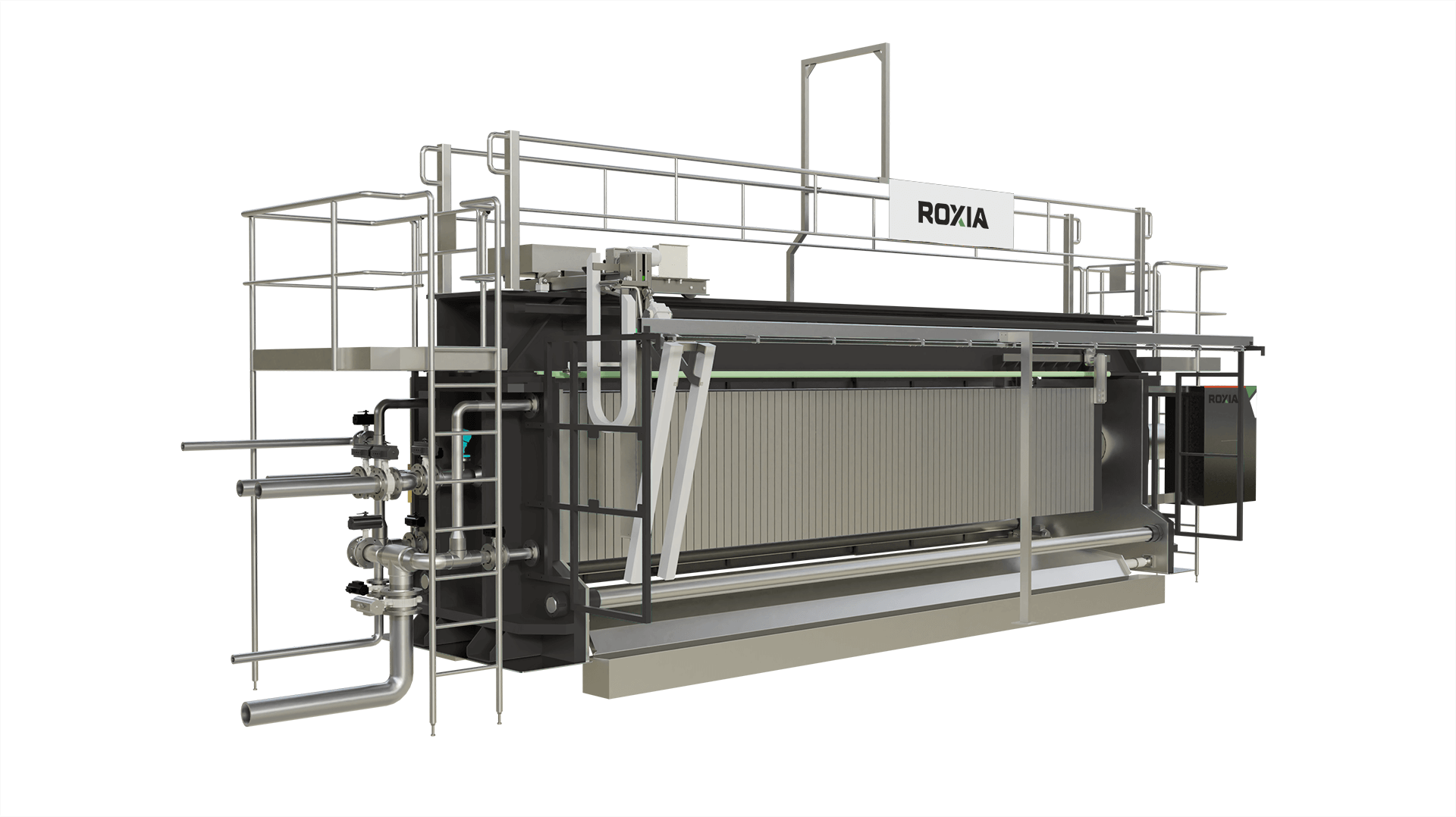

Roxia bietet auch eine detaillierte Analyse des Filtrationsprozesses, Filtrationstests, und Filterauswahl an. Sie erhalten einen kompletten Service über den gesamten Lebenszyklus der Filtrationsanlagen, Ersatzteile und Wartungsunterstützung sowie auch Modernisierungen.

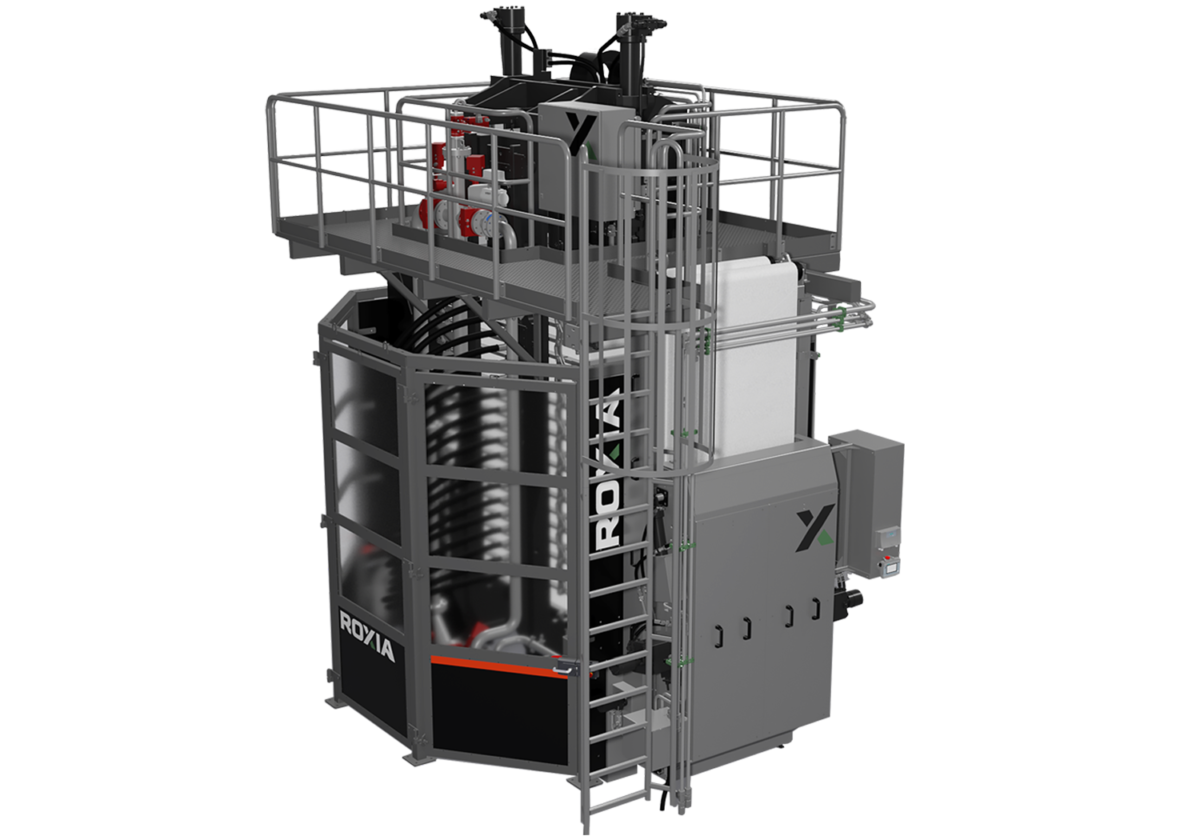

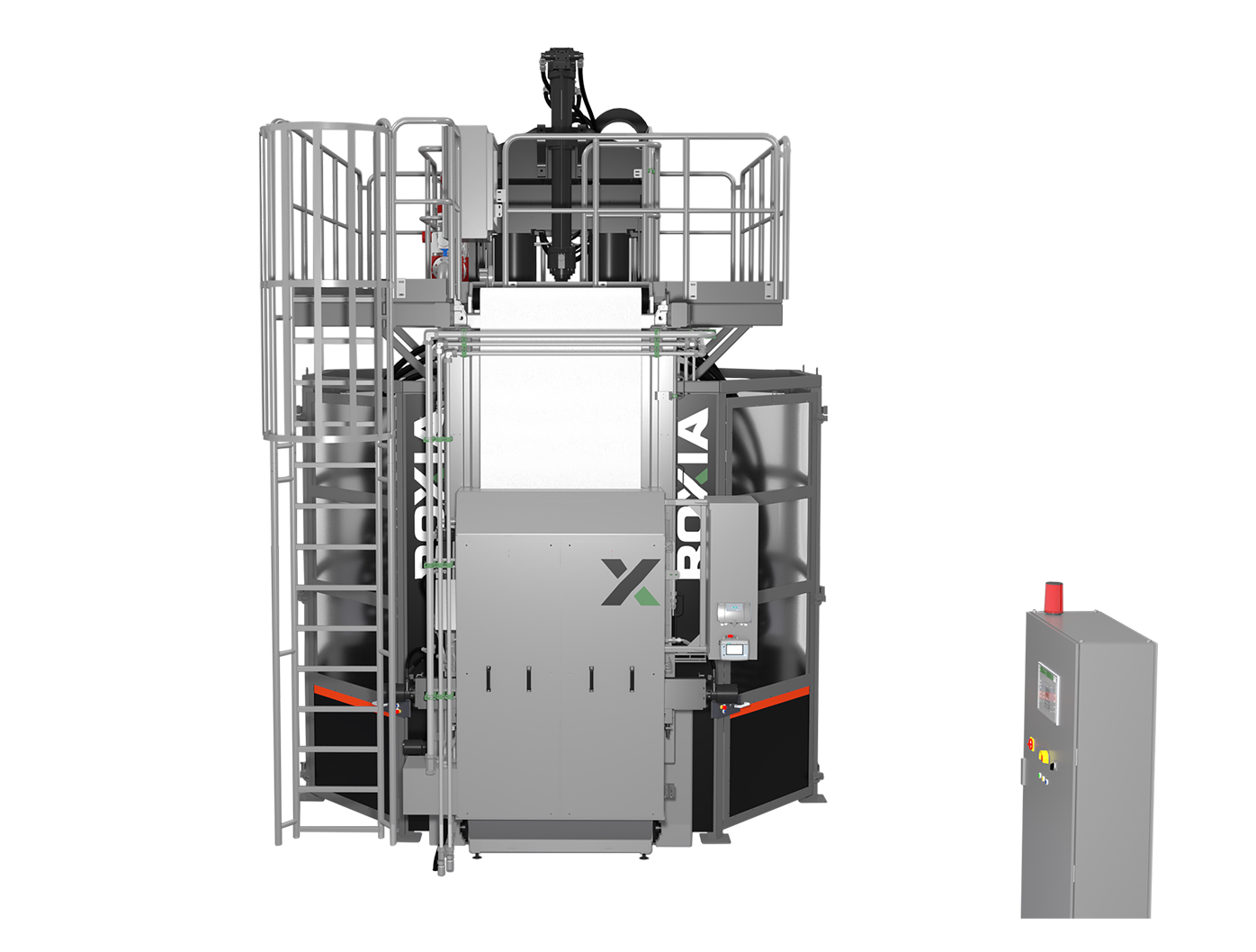

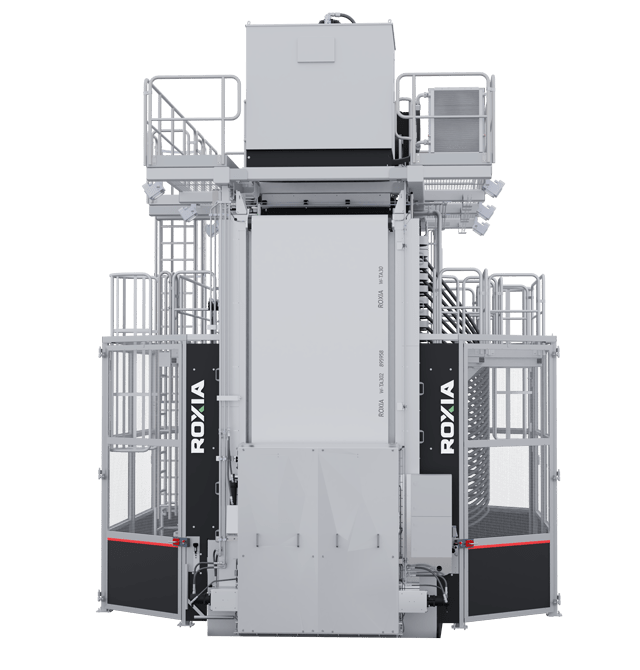

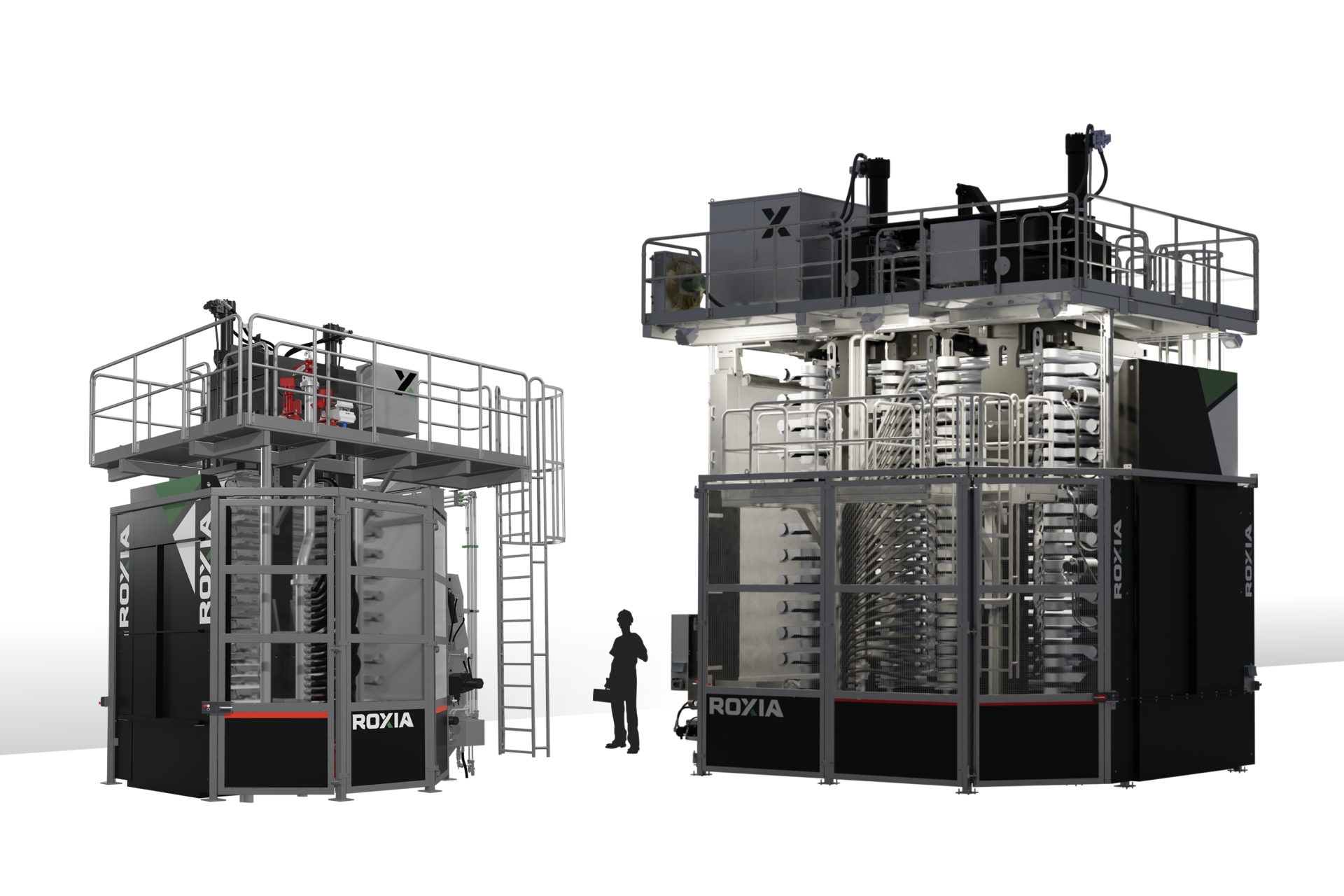

Zusätzlich zum TP Filterpresse, liefern wir ebenfalls komplette Lösungen inklusive der wichtigsten Nebenaggregate.