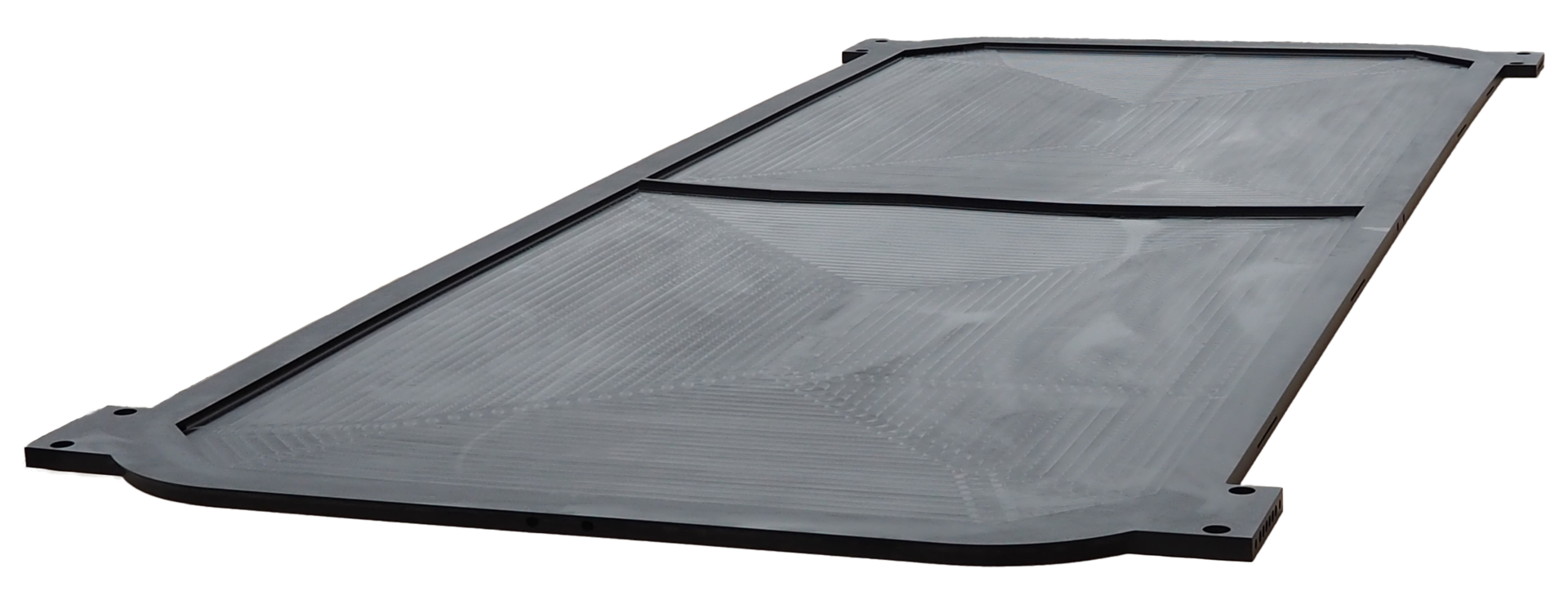

Durable Filter Vats

The Roxia vats have been re-engineered to extend the lifetime not only of the vats themselves but also other filter parts. Vat’s primary functionality is to collect the filtrate in the filtrate collectors and drain it out from the tower press filter. All types of abrasive slurries and filtrates are processed and dewatered inside the filter plates. That is why the plate vats need to be made from durable materials to fight these aggressive conditions.

Roxia filtrate vats and collectors are made from extremely durable, high-density polyethylene (HDPE) which effectively resists any kind of erosion and corrosion. Wear-resistant HDPE enables the vats to last longer which brings immediate savings in spare part costs.

Roxia vats are made from durable, wear-resistant, high-density polyethylene (HDPE) which extends lifetime and saves on spare parts costs.