Improved functionality and extended lifetime

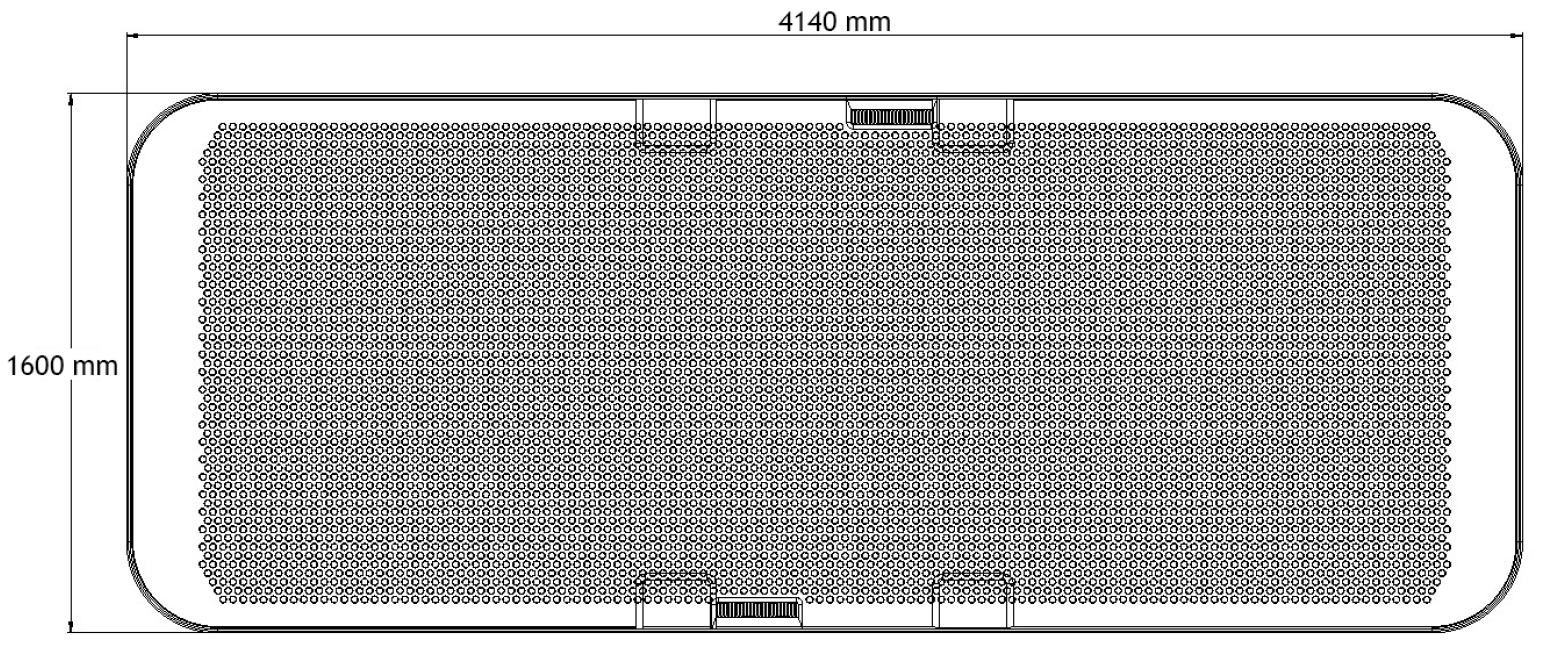

Roxia diaphragms for tower press filters have improved moulding. We use only one homogenous mould to get the best results and professional finishing. This and other improvements are based on valuable practical experience from the field and professional elastomer knowledge. The natural rubber (NR) compound is the most optimal for heavy duty filtration processes to endure immense pressures and have a longer lifetime.

To make overall better diaphragms and extend lifetime, several other improvements have been made. Diaphragm areas against pressing air/water outlet and feed inlet are now reinforced and therefore more durable. Grooves and pipes secure free air/water outlet, improving diaphragm’s functionality. All improvements contribute to better filter availability.

Diaphragm areas against pressing air/water outlet and feed inlet are now reinforced and therefore more durable.