Typical problems of common filter plate seals

- Leaking through joints of seal elements or entire seal area

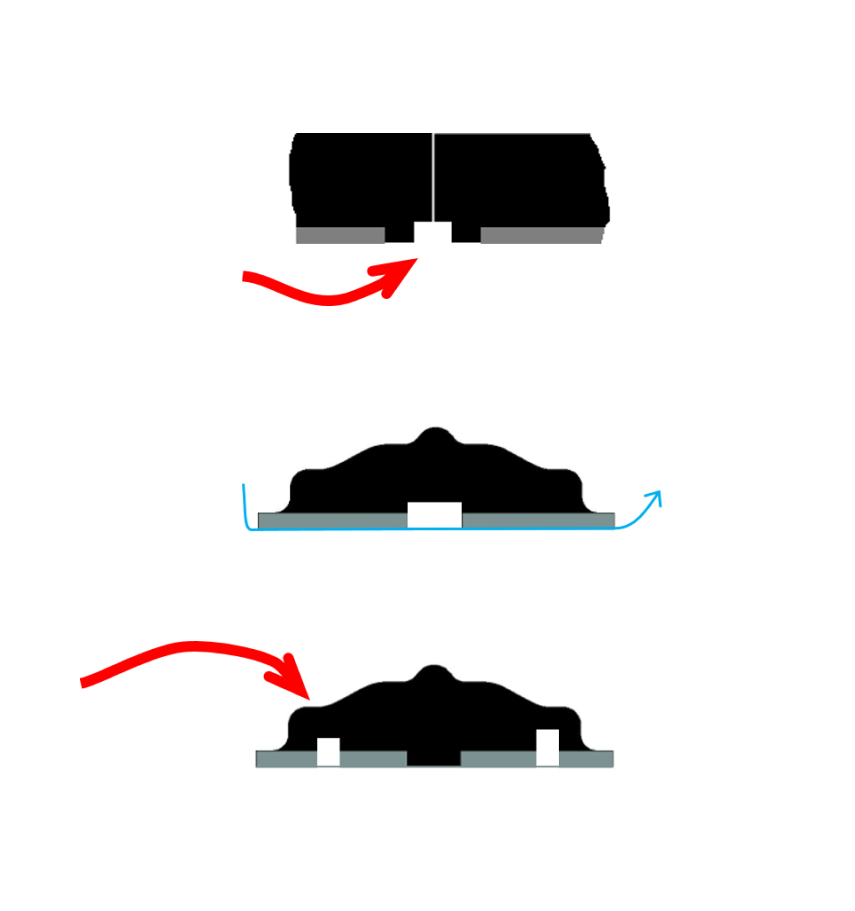

- Seal elements are dropping out of the frame

Description goes here - Leakage under the seal element – unfilled hole between steel stripes means no sealing between the frame and seal element at that exact point

- Unfilled holes in the back side of the seal – when compressed, those are the weakest spots where rubber breaks, slurry leaks and causes damage to other parts of the filter

Description goes here