Filtration testing optimizes existing process

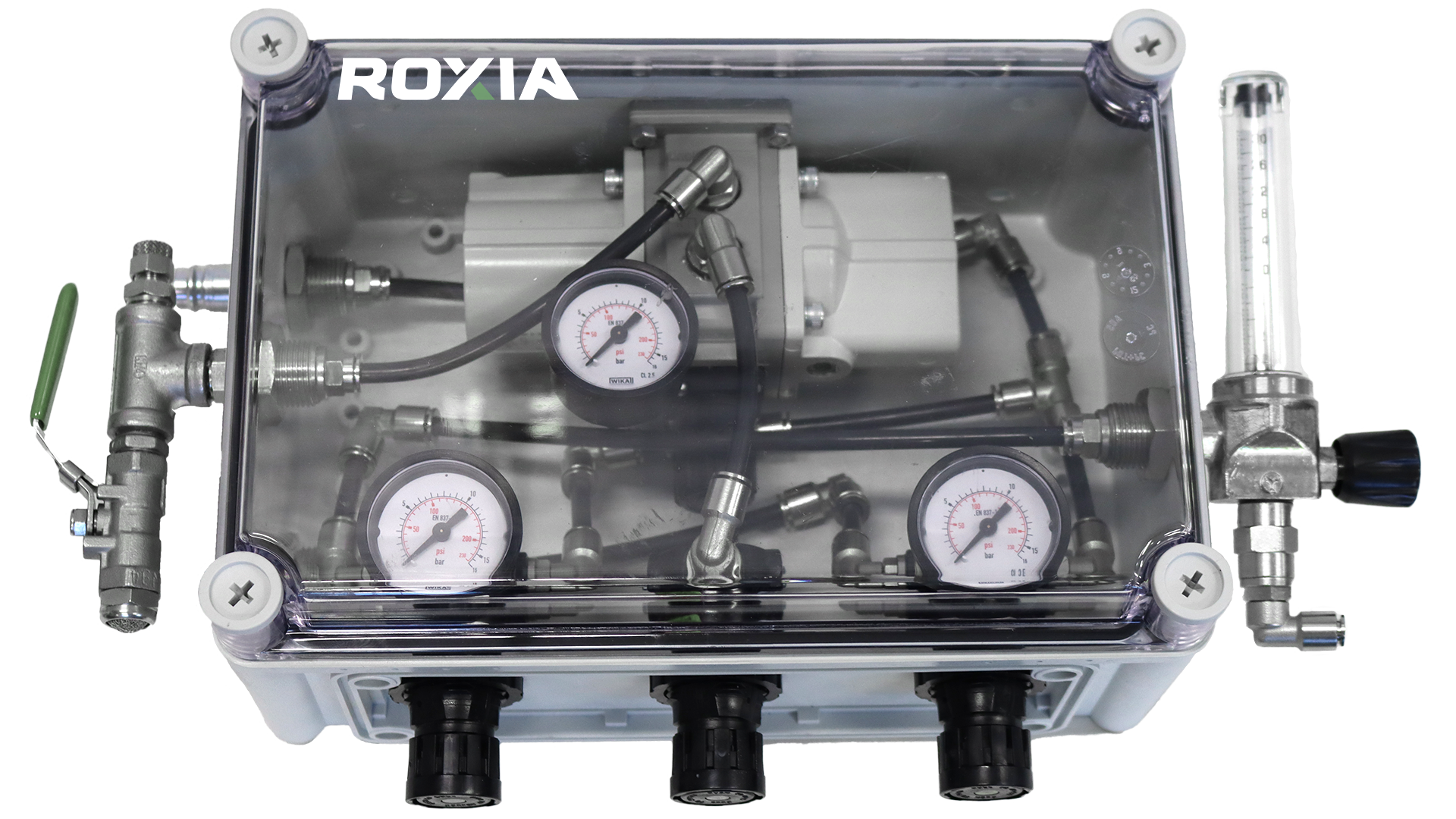

Filtration test service is recommended for optimizing the solid/liquid separation process or when choosing the correct filter type and size. Roxia has many different filter test units, which simulate the operation of the full-size industrial filter and ensure reliable results. Tests can be done on site or in the filtration laboratory. Onsite testing is much faster and does not require interrupting filter’s operation.

Typically, filtered slurry or process conditions keep changing over time. Therefore, filters are often not running in the most optimal way and process performance drops. To improve the situation, filter parameters should be reset and operation of auxiliary equipment checked. Roxia test units make it easy and fast to test the slurry on site, without disturbing the production. Contact us and book an appointment!

Because of the changes in the slurry, it is recommended to regularly perform filtration testing.