Enhance Performance with IIoT Condition Monitoring

Industrial Internet of Things (IIoT) pump condition monitoring can be a solution to help understand pump issues and, better yet, reduce operating costs. If the pump is expensive to maintain or replace and is critical to the process, consider adding IIoT monitoring. There are many things that can be monitored on different pump styles. For instance, a progressive cavity pump should never run dry. Positive head and flow should always be on the suction side of the pump. If this type of pump runs dry for even a half a minute, the rotor and stator can be permanently damaged. Adding vibration sensors and flow meters can help diagnose and stop a pump before serious damage occurs. Main bearings, gear boxes and motors can be monitored so increasing vibration can be detected and an e-mail or text can be sent to relevant personnel to diagnose and fix a small problem before it becomes significant and costly.

What Data can be Monitored by IIoT?

Immense data can be captured from an integrated frequency drive. Any instrumentation that resides in the area of the pump that provides input to pump performance can be tapped into and monitored from a cloud based portal. Alarms will be displayed on the cloud-based portal but e-mails or text messages can be sent to relevant personnel for any alarm.

Some of the benefits of IIoT condition monitoring are:

- Real-time feedback on asset performance

- Quickly identify assets in trouble and, in many cases, fix the problem

- Lower maintenance costs, safer work environment and less downtime

Any asset that has digital or analog instrumentation inputs can be monitored. Instrumentation has become much less expensive and easier to install. Some call this instrumentation “lick and stick.” It can be bolted on, use magnets or adhesives. Virtually any asset including pumps can use IIoT monitoring. Some areas or instances where IIoT condition monitoring can help are:

- Dangerous or dull locations

- Where plant safety is an issue

- Where compliance is involved

- Assets in hard to reach areas

- Assets under constant repair

- Assets with a high cost of repair

- Assets that through optimization can increase production and increase revenues & profits

- Pumps located in distant or remote locations

Condition Monitoring Improves Pump Station Operations

Roxia provided smart pumping solutions for a waste management company EKJH in Finland. The company had a remote unmanned pumping station where the control system was old and out of date. Personnel had to travel to the station several times a week to take readings and make adjustments to pumps and other assets. The smart valve and pump manufacturer provided an updated control system to replace the existing system for half the cost of a new control system. Now the owners of that remote pumping station can sit in offices 80 miles away to make system adjustments and all the readings are real time cloud-based. If there is an alarm, the owners get an e-mail, and they can log in and determine if a site visit is required.

IIoT Solution for an Aeration System

The same wastewater management company contacted the manufacturer last year about an aeration system for its leveling pond. It had a problem with the pond freezing during winter and generally low oxygen content in the water, which resulted in foul odors. The manufacturer recommended that the aeration system should be fully automated and operated under the same platform as the remote pumping station. The goal was to supply the lowest total cost of ownership. Roxia partnered with a company that specializes in surface aerators because the project required compressors and energy efficient oxygen transfer while keeping the pond surface from freezing. Roxia was able to gather all the data from the aeration units and provide an automatically adjusted system that operates according to weather and water conditions, as well as incorporate the remote pumping station. The EKJH waste management company has been pleased with the solution.

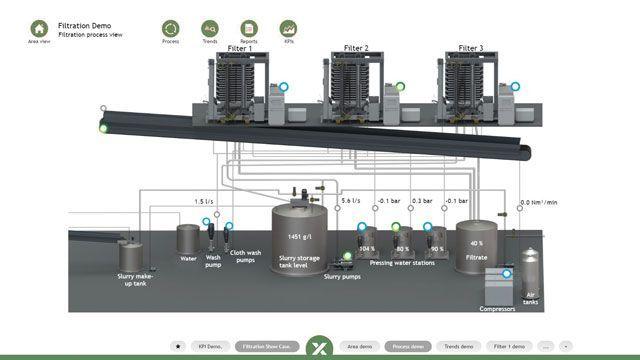

Last year, the IIoT provider added vertical tower pressure filter monitoring on three pressure filters also in Finland. These machines are highly automated and have many instruments and inputs to monitor. However, the manufacturer did not add any additional instrumentation to these machines. It began to analyze the data and provide dashboards so the plant could better understand its issues.

Roxia IIoT Solution Unveils How are Machines Really Running

The plant assumed the machines were running at a high utilization rate. Over time, the provider was able to prove that the machines were often running at 60 percent or lower usage rates. One of the main reasons the machines were running at these low usage rates was simply because the slurry tank that feeds the machines was often too low to provide the flow to the filter machines. So, the filters had to wait until there was enough slurry. The manufacturer was also able to analyze both high-pressure spikes in water pressing that damage filter plates, diaphragms and seals. Also, high air consumption of one machine compared to the others typically indicates failing diaphragms or seals that are causing pour performance. This one customer is saving money on downtime and getting increased production now that they understand some of their issues.

Any plant can capture data, but if it does not have an effective way to analyze the data, then it is useless. IIoT monitoring is proving to be an analysis tool that is benefiting many customers.