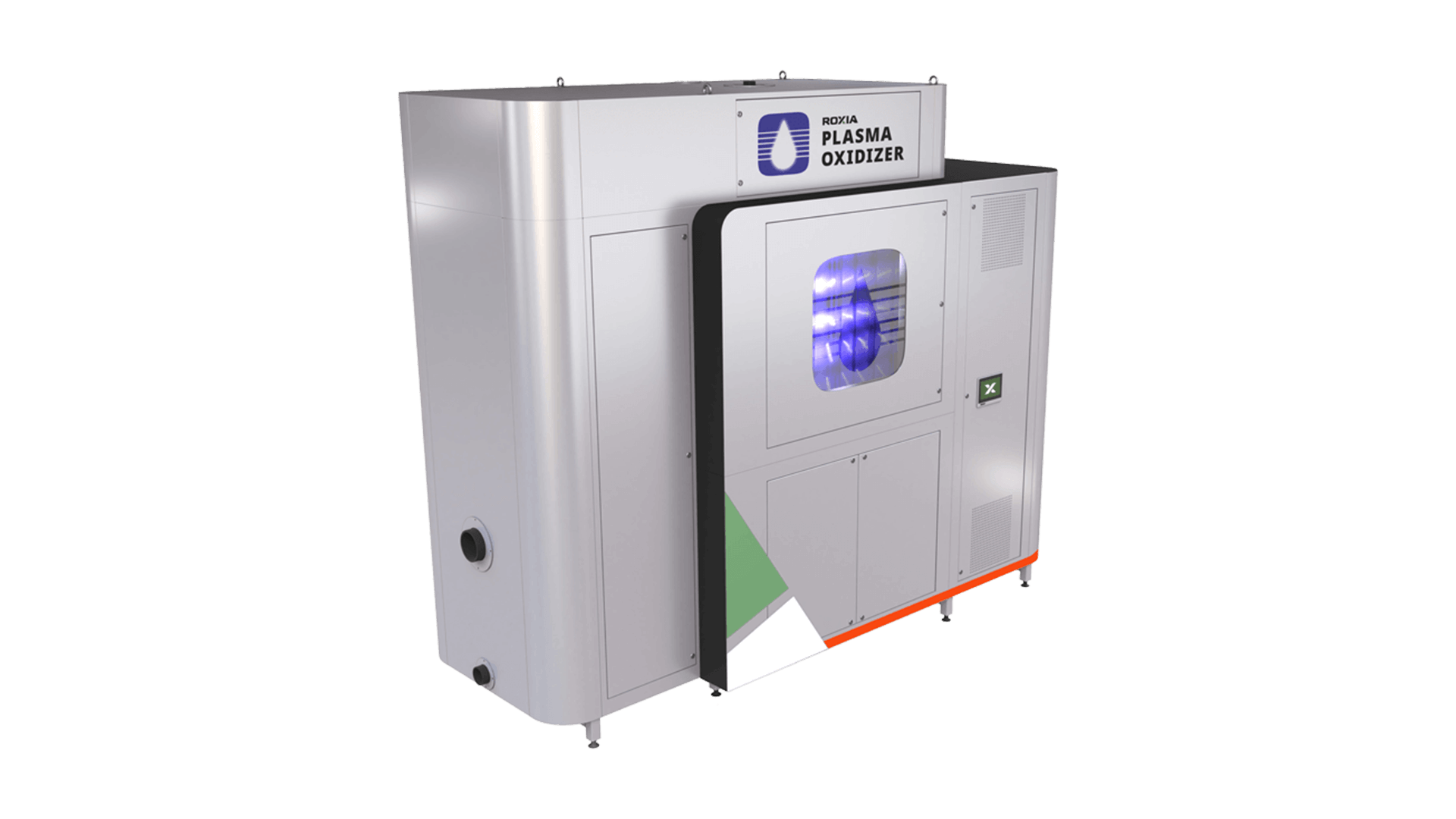

Roxia Plasma Oxidizer Replaces Treatment Chemicals With Plasma

Roxia Plasma Oxidizer (RPO) is unique industrial water treatment technology as it uses non-thermal plasma in direct contact with water to destroy dissolved organic pollutants. Purified water can now be a result of completely chemical-free process. RPO is considered to be the paradigm shift in oxidative water treatment and industrial water purification. It eliminates the need for transportation, storage and handling of risky disinfection chemicals, thereby mitigating costs and environmental risks. Roxia Plasma Oxidizer is safer, more economical and environmentally friendlier solution.

Roxia Plasma Oxidizer is a superb alternative to ozone, UV and chemical water treatment.