Roxia Plasma Oxidizer™ (RPO) utilizes non-thermal plasma for water treatment. The system contains electrode stacks that generate special types of electric discharges to create an ambient-temperature plasma field inside a reactor.

The water to be treated is then allowed to pass through the plasma volume with high specific plasma-water contact surface area. Maximizing the contact surface area allows for abundant OH-radicals to be formed on the interface, contributing to effective oxidation of dissolved pollutants.

Plasma Water Treatment

Intuitively, generating electric discharges to treat water may sound energy intense, but the basis for the Roxia Plasma Oxidizer process is in an accurate focus of electric energy right where it is needed on a molecular scale, which translates as a sophisticated means of igniting the desired oxidation reactions at minimal energy input. Various reactor configurations with different kinds of plasmas have been studied for water treatment applications. It is generally accepted that a straightforward gas-phase discharge brought in contact with liquid water is a better solution than attempts to break the discharge through water with submerged electrodes.

Again, intuitive as it might be to create the plasma right through the water for ultimate contact, this approach suffers inevitable energy losses as it relies on water vaporization to form a conductive pathway for the discharge propagation. The RPO approach combines the very high plasma-water contact surface area with the advantages of a simple gas-phase electric discharge.

Thermal and non-thermal plasma

Plasma, the fourth state of matter, is formed when ionized air or some other gas or gas mixture is ionized. Ionization of air enables an electric current to pass through it. In perhaps more colloquial words, plasma basically means electric discharge, such as a lightning strike, or what you see inside fluorescent lights, or the spark between a car engine spark plug’s terminal. It is convenient and important to separate types of plasmas into thermal and non-thermal ones.

Thermal plasmas are very hot, like lightnings and welding arcs (up to thousands of degrees), whereas non-thermal plasmas remain closer to ambient temperatures. The thermodynamic difference stems from molecular movement: in thermal plasmas, both electrons and ions in the gas are energized, while in non-thermal plasmas, only electrons are. For water treatment purposes, there is no reason to spend energy in energizing ions, which means that non-thermal plasmas are preferred. The reason is that only high-energy electrons are needed for generation of OH-radicals in a very straightforward reaction:

e− + H2O → e− + OH + H

The equation describes how an electron (e-) colliding with a water molecule (H2O), with a very high kinetic energy, splits it into an OH-radical and what is called atomic hydrogen (H). The atomic hydrogen is scavenged by ambient oxygen to form a hydroperoxyl radical, also an oxidant, and the OH-radical will react instantaneously with surrounding substances. Since the radicals are formed from the treated water, it can be said that in plasma treatment the water actually purifies itself!

OH radicals and oxidation

Due to the high reactivity of the OH-radical, it is inherent that many of these will be consumed in useless decay reactions. On the other hand, it also means that residual OH-radicals are not found in the treated water through the output of the reactor. As the efficiency of the RPO process lies in the appropriate focus of energy into heating electrons and not ions, the efficacy is based on the sheer abundance of the OH-radicals on the plasma-water interface. Indeed, as the non-thermal plasma embraces a water droplet, OH-radicals keep forming and disappearing for as long as the contact remains.

Formation of ozone

Another important oxidant formed in the process is ozone. Ozone is produced from the oxygen in the ambient air, and indeed, the process efficiency can be ramped up with an accessory oxygen concentrator coupled to enrich the inside oxygen concentration. Enriched oxygen concentration has been observed to even double the plasma oxidation energy efficiency. While important, however, ozone plays a secondary role in the oxidation process as the OH-radicals are generally attributable to 60-80% of the oxidation work. The roles of these oxidants depend on the composition of the wastewater; OH-radicals can react with compounds that exhibit a refractory character towards oxidation with ozone.

Roxia Plasma Oxidizer Technology

The original motivation for direct plasma treatment of water was to create a fundamentally more economical alternative to conventional ozonation.

1. The core idea

Generate the oxidants right where the water is and harness the power of OH-radicals, whose formation is a notable benefit when the plasma is brought in contact with water.

2. Robust system

It was also considered important in the early design phase that the system should be very robust, tolerate harsh conditions, have no moving parts and exhibit no electrode erosion attributable to electric discharges.

3. Low maintenance

These features were finalized into the current RPO design and the result is really a low-maintenance system that brings only stainless steel in contact with the water, no moving parts and zero observed electrode erosion.

4. Tolerates high-conductivity water

Another distinctive feature for RPO is its ability to tolerate high-conductivity waters, which is not an obvious feature for a system that brings electric discharges together with water.

5. Chemical-free

Roxia Plasma Oxidizer can be operated with no extra chemicals, using only electricity.

The first generation RPO was launched with 2-kW plasma output power at standard maximum capacity of 25 m³/h. For larger capacity requirements, Roxia built the first 10-kW prototype in late 2020 capable of running 240 m³/h water through plasma oxidation.

Roxia Plasma Oxidizer Applications

The majority of suitable applications deal with the destruction of organic pollutants. Some inorganics may also be well susceptible towards a reaction with the oxidants: metals can be removed from organometallic complexes and oxidized to a higher valence state and form oxides (some metals such as Mn and Fe will thus precipitate out) nitric and sulfuric species can be oxidized into nitrates and sulfates etc.

Aromatic hydrocarbons and other organic pollutants with unsaturated double bonds in their molecular structure are facile targets for plasma oxidation. The simplest structures are often the most refractory ones, such as organic acids with low molecular weight, like formic and oxalic acid. Conveniently however, these kinds of compounds may often be environmentally benign and easily biodegradable. While these guidelines can be useful for estimating process applicability against given pollutants, it is important to understand that they are generalizations among a horde of typical scenarios and a throng of essential exceptions.

Remarkable performance in phenol degradation

Phenol is a typical model substance used in studies of new oxidation technologies to provide a point of comparison in performance and energy efficiency. Roxia Plasma Oxidizer technology has proven remarkable performance in phenol degradation yielding 88 g/kWh removal efficiency in operation with ambient air and an even more impressive yield of 138 g/kWh at enriched oxygen atmosphere (initial concentration 100 ppm).

Efficient furfural removal

Another study for furfural removal from 500 ppm yielded 133 g/kWh efficiency in basic solutions and 182 g/kWh in acidic ones, which demonstrates very high figures and gives an example of the effect of pH on efficiency. It is worth pointing out, however, that on the contrary to the experiences with furfural, high pH is often beneficial for the oxidation energy efficiency due to certain pH dependent ozone reaction pathways, which emphasizes that the water quality is usually the major variable. Large groups of other pollutants with cyclic molecular structures include for example pharmaceuticals and pesticides, most of which have one or more cyclic moieties in them. A large group with many individual compounds tested for plasma treatment as pharmaceuticals are discussed in more detail at a later paragraph.

RPO destroys organic acids

Organic acids like formic, oxalic, acetic and succinic acids are also popular model compounds. They exhibit lower reaction rates with oxidants and for these properties provide good subjects for scientific studies. In practice, they rarely pose a problem due to natural biodegradability and overall harmlessness. These substances with low molecular weight are typically more refractory than the heavier and aromatic hydrocarbons, and while the Roxia Plasma Oxidizer technology has shown comparatively high oxidation rates with those as well, few practical applications are encountered in industrial operations.

Plasma eliminates 90-99 % pharmaceutical residues

Pharmaceuticals compose the widest single group of chemicals studied for degradation of various waters with the RPO technology. More than 40 chemicals have been observed from municipal, hospital and institutional wastewaters. The technology has been proven to substantially cut the pharmaceutical load to the environment when installed either to a point source, such as a hospital sewer line before connection to municipal network, or at the end of an WWTP to serve as tertiary treatment.

Especially suitable for hospital wastewaters

Higher number of pharmaceuticals with higher concentrations occur in point sources like hospital sewage, which make it a convenient place to cut the content before dilution in the network. Even the complex mixture at a very high COD characteristic to untreated hospital sewage has been observed to be a feasible medium for RPO treatment, as the results have shown that the pharmaceuticals occurring in nano- to microconcentrations are to a large extent degraded below analytical level of detection. Since the transformed species are not visible in analyses, unless specifically determined, further studies have been conducted to ensure that possible transformation products are also affected: previous works with the anti-epileptic drug carbamazepine, any identified transformation products, including those from partial oxidation in the beginning of the process, have been observed to degrade further beyond identification.

Eradicating dissolved oil

Spill accidents with fuel additives like MTBE and dissolved oil residues pose great hazards for aquifers and are known to render ground water undrinkable. Roxia Plasma Oxidizer has demonstrated very high efficiency in destroying both dissolved oil fraction and MTBE at a very acceptable energy consumption. The non-selective process readily oxidizes any such compounds, producing safer water for reuse or disposal.

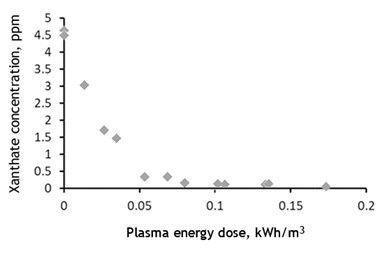

Remove xanthate residues from mining waters

Another high-potential and specific application is the destruction of xanthate residues from mining waters. Previously, there has not been an appropriate industrial-scale process to remove these flotation aids in a reasonable manner. Experiments with RPO in this application demonstrated a very low energy requirement for complete removal starting at typical concentrations, as visualized in Figure 2. Roxia also offers other comprehensive solutions for industrial wastewater treatment.

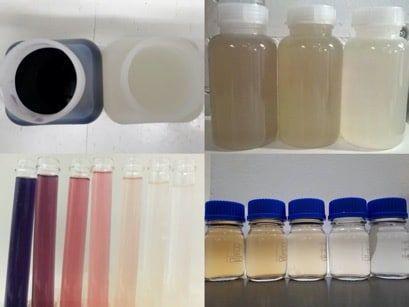

Plasma removes colour

Color removal is another typical task for an AOP. While high color and turbidity naturally exclude processes relying in UV light, plasma treatment is insensitive towards turbidity because the oxidants are produced on the gas side of the liquid surface and no light transmission through the liquid media is required. Color removal can be thus very efficient, the efficiency depends on various treatment parameters and the composition of the color itself. Figure 3 below visualizes color reduction in plasma treatment of various wastewaters.

Disinfection of process waters

One of the key applications for plasma treatment is disinfection of process waters. The parallel benefits complementing disinfection include destruction of any other organic pollutants, dissolved oil contaminants and removal of odors and residual color: plasma-treated water is fresh and colorless. Extremely good results have been obtained in microbial control of process waters with very modest energy requirements at <0.05 kWh/m³. Such applications where the specific energy dose requirement remains very low, large volumetric capacities can be achieved with relatively low investment and operational expenses. Plasma-activated water is well-known to convey disinfection capacity to the receiving water body and inactivate bacteria and viruses with a lasting effect, which together with the negligible maintenance requirements make the RPO a very attractive state-of-the-art solution for process water disinfection.

Author

Petri Ajo is the Head of Roxia Environmental Technologies. B.Sc. (Tech), Environmental technology, 2012, M.Sc. (Tech), Environmental technology, 2013, Doctor, Sc. (Tech), Green chemical engineering, 2018