The Deep Mine project at Outokumpu’s Kemi mine consisted of expanding the mine to up to 1000 meters depth. This required a completely new infrastructure to enable efficient ore extraction and sufficient mining processes. The expansion included a wide variety of sub-projects for which Roxia provided automation, instrumentation and electrification.

About Kemi Mine

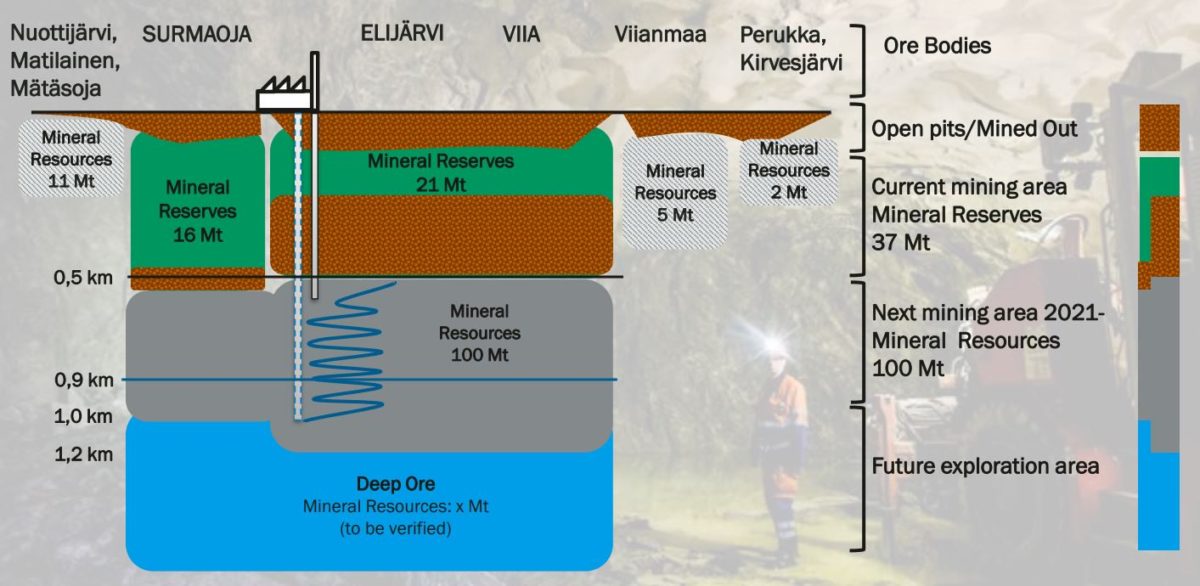

Outokumpu’s Kemi Mine is the only chromite mine in Europe and the biggest underground mine in Finland with an annual extraction volume of 2.7 million tons. Kemi Mine was established in 1968 and operated as an open pit mine until 2003. In 2003, the mining was moved to underground mining and the open pit was completely closed in 2005. Now, 20 years later, the underground mine will be expanded, and the lifecycle of the mine will be secured for at least the next 20 years.

Chrome concentrates are produced chemically in a gravity-based separation process. Both concentrates are transported by road to the Tornio ferrochrome factory which produces ferrochrome pellets for the Tornio steel factory. The steel factory manufactures various types of steel and steel products, where ferrochrome is needed.

Kemi Deep Mine project

The Deep Mine projects started in 2017 with the purpose of deepening and extending the mine from 500 m to 1 km depth. At the same time, a completely new infrastructure for enabling efficient ore extraction and mining processes was planned.

In terms of infrastructure, the most significant structures were the new main level, the new lifting shaft, and a 104-meter-high lifting tower on top of the shaft with lifting machines and new conveyors which will feed the ore to the concentrator.

Automation Delivery

During the last three years, Roxia Automation delivered the expansion for the existing Mine DCS system as a turn-key solution. The Deep Mine project consisted of one major contract and several sub-projects related to automation, instrumentation and electrification.

Roxia started working on the Deep Mine project in 2020 and it is now completed with excellent results. All test runs have been passed without errors and the delivery is accepted without defects.

The cooperation between Outokumpu and Roxia continues with after-sales services and continuous development at the Kemi Mine.