Numerous chemical manufacturers of all types utilize pressure filtration for solids/liquid separation. In my more than 25 years of experience in pressure filtration, I have witnessed countless pressure filters in operation. I can honestly say that at least 70% of the pressure filters I have witnessed in operation, most have been operating significantly below desired production rates, were producing less than desirable product quality and had extremely high operating expenses.

The world is constantly growing more global and competitive. In many cases companies that manufacture large scale pressure filtration have significantly reduced their customer support and service engineering staff that aid users of their pressure filtration machines. The result is that a customer will get start-up and commissioning service after the sale but after that the user is on their own to maintain and operate this machine. With competition for skilled technicians, the operators that received training for the new machines may have moved on to new companies within 2 – 3 years. Thus, the owner of the pressure filter loses the experienced personnel to run the pressure filter optimally.

Varying conditions affect filter performance

Pressure filters have numerous input that have varying conditions that can and do affect machine performance. For example, as the main slurry feed pump wears it can have drastic reductions to operating performance over time. The feed pump is just one of the many variables. The slurry tank, pressing water tank, air tanks and a lot of other variables can also affect machine dependability and product quality. Many pressure filters are highly automated and managing programming and operating maintenance can be highly challenging to operating staff.

Roxia has recognized these challenges and has 42 plus years of pressure filter manufacturing, sales and service support of these machines. Roxia has developed a proprietary pressure filter digitalization monitoring of pressure filter performance and advance warnings of potential or existing component failures that affect machine performance. Roxia’s digitalization package can be added to Roxia pressure filters but also can be added to any type of pressure filtration that has digital or analog instrumentation on the machines that help operate the machines.

Smart Filtration and IIoT

In the following paragraphs I am going to try to explain how we helped one user of three pressure filters to improve their process. The customer was a mine in Northern Finland. Roxia’s headquarters are also in Finland. The mine was using three vertical tower pressure filters. Roxia added one Roxia Malibu™ Smart Cube to start monitoring and help provide optimization of the machines. Roxia connected one LAN cable to the PLC of the filters and began to monitor more than 300 data points on those machines. Roxia worked with the plant owners to set up KPI (key performance indicators) for those machines.

When monitoring first began it was assumed that all the machines were highly utilized. But in fact, these filters were severely underutilized. Through digital monitoring, it was noticed that machine 3 was waiting up to 4 hours every day for auxiliary equipment. The manager of the filtration plant also spent 2 – 3 hours every Monday calculating last week’s production from various systems and excel pages for the filter plant. Now with smart monitoring everyone in the plant can see hourly production from the filter plant. Also, if these waiting times and production on machine 1 and 3 can be improved to the performance of machine number 2 then, production could increase by more than 88,000 kilograms per day. With a yield of 25% and zinc at $1.26 per U.S. pounds that could mean more than $18 million more saleable product per year.

Remote monitoring benefits

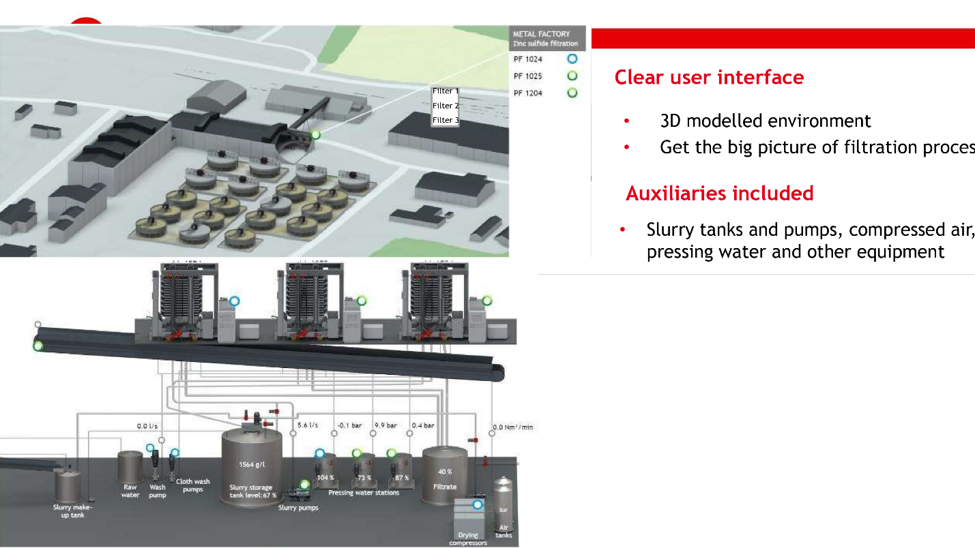

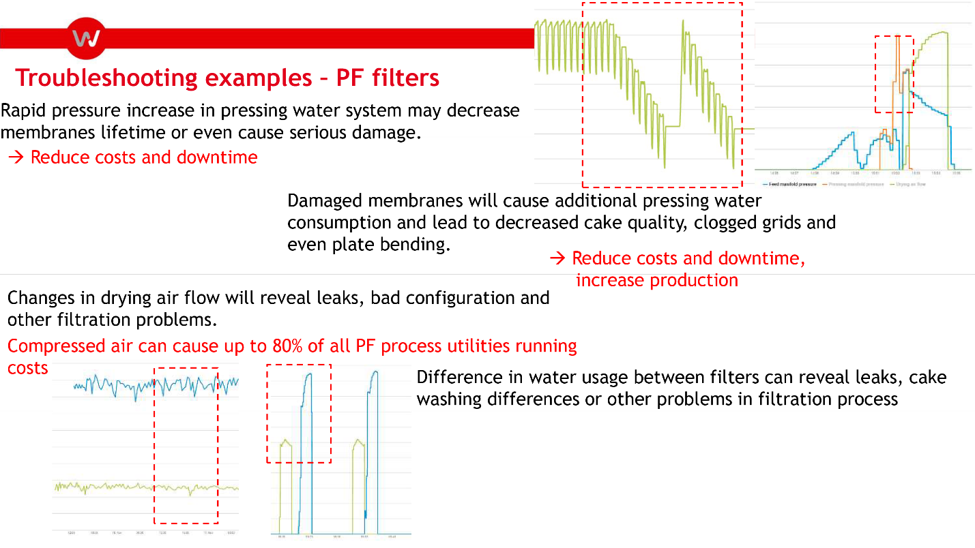

Roxia provides digital twin imagery of the process and plant so that all stakeholders can visualize the process right on their smart phones, tablets or PCs. If there are any alarms Roxia Malibu will send an e-mail or text to pertinent personnel to address issue early before they become more costly damages. Through remote monitoring of this customer’s process Roxia noticed that the customer from time to time had issues with both the pressing water system and the compressed air systems.

One concerning issue that was recognized was that both systems had high pressure spikes in air and water. These spikes can lead to diaphragm, seals, cloth and worst-case plate damages. If a plate pack is damaged by one of these high-pressure spikes, then the total repair may approach $1M and significant downtime of that machine. Also are seals, diaphragms or the cloth is damaged they may bleed off expensive air and experience poor product quality.

Why use IIoT and Roxia Digital Solutions?

Roxia manufactures pressure filters and ceramic disc filters as well as various valves and pumps. All Roxia pressure filters are now being offered with Malibu monitoring as part of the standard offering. Most customers need continuous monitoring and help to keep their filters operating at peak performance. Roxia also has a very significant group of service and support engineers to help with continuous training and service contracts. Pressure filtration properly run and managed can be a fine-tuned machine. But if not managed well the filtration plant can become a significant operating cost and bottleneck to the operation. Digitalization is one means to ensure your valuable plant assets keep running at peak performance, eliminate unwanted operational costs and eliminate unwanted downtime.

Roxia Digital Solutions can be added to complete process monitoring or any type of OEM machine with digital or analog outputs. Also, additional instrumentation can be added to provide higher levels of monitoring. DCS or SCADA systems perform well and control the process. What is missing from most DCS or SCADA systems is a higher level of diagnostics utilizing machine learning and artificial intelligence (AI). Instrumentation costs have reduced and virtually any asset can be monitored for enhanced performance and cost savings. Roxia Malibu will not replace the DCS or SCADA but rather is add on that performs complex analytics to improve results in both the process and operational expenses.