High Efficiency & Low Costs

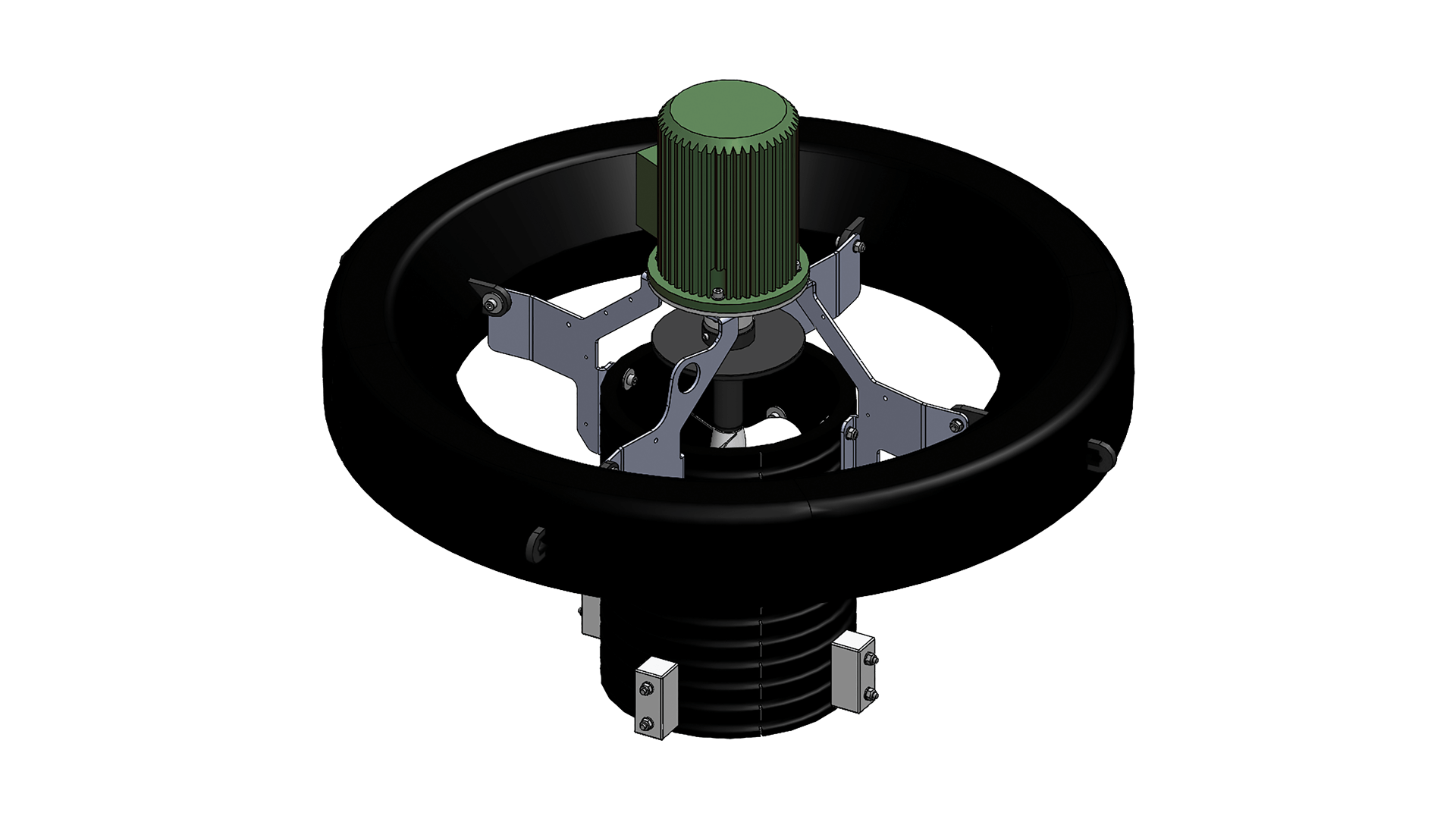

Roxia Floating Aerator efficiently transfers and disperses oxygen into the wastewater. The floating design allows fast and easy installation without costly construction. The aerator’s features bring together high efficiency, low initial investment, and low energy consumption.

Wastewater aeration does not need a complex infrastructure. Roxia Floating Aerator is an effective and cost-efficient solution.