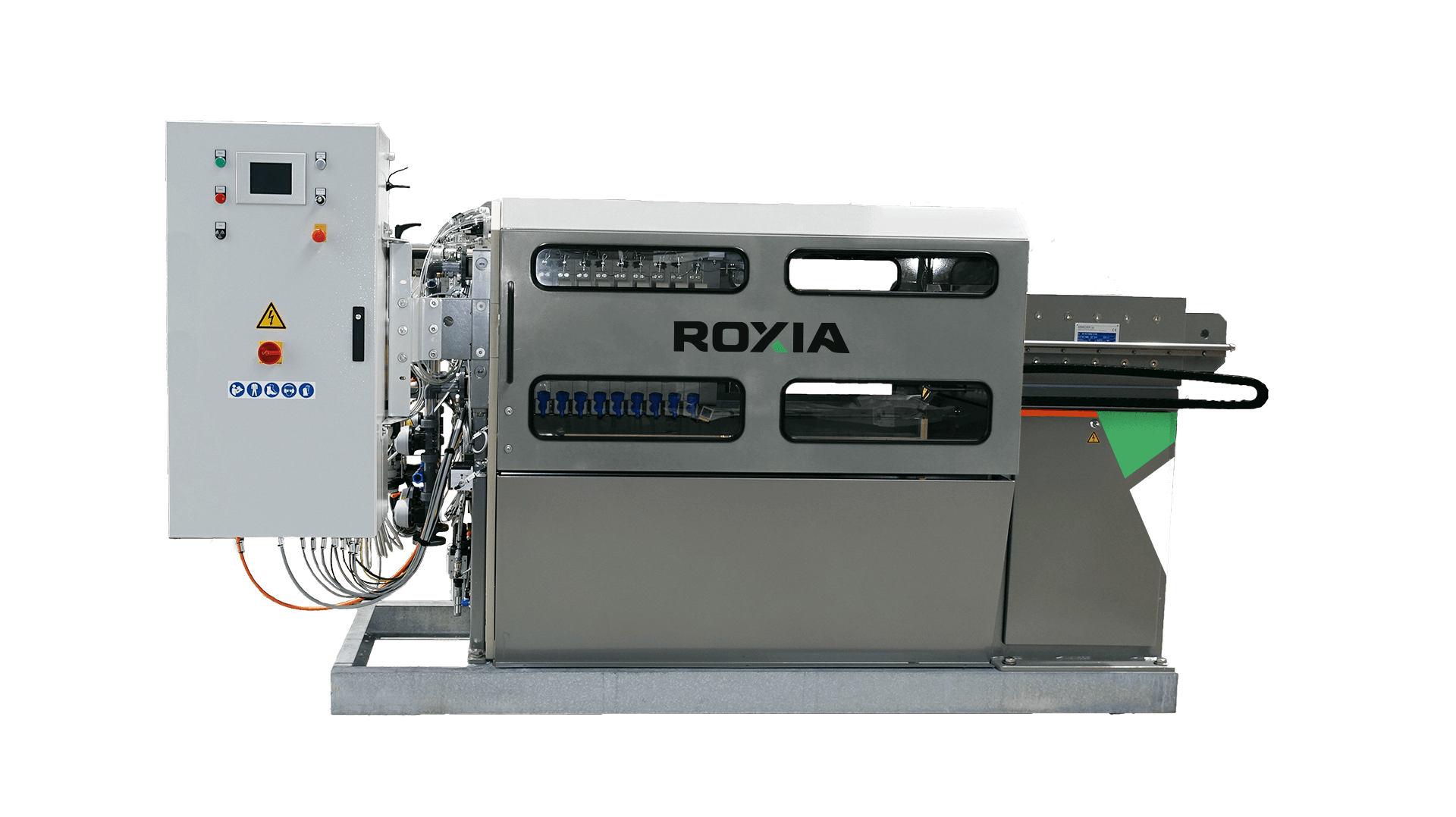

Reliable unattended cake discharge

- Automatic filter press – all stages of operation are fully automated.

- Unmanned availability above 98 %, only periodical inspections required.

- For safety and performance, sludge filter press is equipped with several error detecting functions.

- Optionally with Roxia Malibu™ online portal for remote monitoring and performance analysis.

Roxia Smart Filter Press™ runs self-diagnostic in each filtration cycle, making it a fully automatic self cleaning filter.