Filter presses are widely used in various industries for solid-liquid separation processes. It is a common misconception that it is used solely in mining.

There are many applications in the food, drug and chemical industries and many more where the requirement is a slurry of some form that needs to be dewatered for transport. Call it a rule of thumb.

The Role of Filter Cloth in Process Efficiency

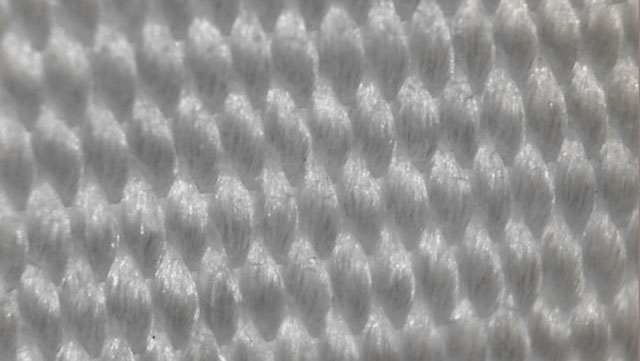

For every filter press and every filter press application the common thread – pun intended – is the filter cloth.

With all the moving mechanical parts in a filter press it is important to highlight the crucial part the correct cloth plays in filter efficiency, filter cake quality and filtrate clarity. Getting it wrong will affect the process up and downstream and not just increase filtering time but will impact operational costs, maintenance time and in some cases have an environmental impact.

The primary function of any cloth is to capture and retain solid particles while allowing liquid to pass. To do this the cloth material and cloth permeability needs to be matched with the process.

Easy, Right? Well… its a start.

Key Considerations in Filter Cloth Technology

There are many other aspects to filter cloth technology that is important and have to be considered:

- Filtration Efficiency: The right filter cloth will ensure effective particle retention and clear filtrate.

- Cake Formation: A suitable filter cloth material and design will facilitate uniform cake formation, minimizing cloth blinding and uneven cake.

- Chemical Compatibility: Cloth compatibility prevent degradation due to chemical reaction and temperature and maintain long-term performance.

- Mechanical Strength: Filter cloth needs sufficient tensile strength, abrasion resistance and durability to withstand the mechanical stress of the filtration process and to do this repeatedly without tearing or premature failure.

- Cleaning and Maintenance: The correct filter cloth will be easily cleanable with backwashing, chemical cleaning, or mechanical cleaning methods.

- Product Quality and Yield: The choice of filter cloth impacts the quality and concentration of the filtered cake.

Consulting with Experts for Optimal Solution

Taking into account how critical the filter press is in the operation and the various factors involved in selecting the right cloth, it is important to consult with the manufacturer or supplier to ensure the correct equipment is used.

As a filter press and cloth manufacturer Roxia can guide and assist on the nature of the filtration process and the characteristics of the material being filtered to get the right fit for the application.

At Roxia we have over 40 years of experience in filter technology and matching the right cloth to the right application.

Over the years we have been known by many names but we have stayed close to our customers ensuring our expertise and know-how can be counted on. Our entrepreneurial spirit ensures that we are constantly evolving and bringing new technology to the market.

If you have any queries regarding your process and filter cloth give your nearest Roxia a call.