Wallac’s operations produce wastewaters containing phenolic ethoxylates, organics that are known to be hard to remove from wastewater and they must not be discharged to the public sewer network. Previously, the only alternative for managing the wastewaters with difficult chemicals was transportation a few hundred miles away to a hazardous waste management facility. No realistic solution existed for onsite treatment before the introduction of Roxia Plasma Oxidizer: “We had no alternative”, says Janne Ahonen, HSE-Expert at Wallac.

Roxia’s alternative to expensive wastewater handling

Wallac Oy learned of Roxia’s plasma technology from a news piece about the removal of pharmaceutical residues from hospital wastewaters. In Turku, Finland, they have one of the group’s largest R&D and manufacturing units. Wallac Oy is part of PerkinElmer group that is one of the leading health technology companies in the world. The Turku site develops and manufactures equipment, reagents and software, and conducts research on different processes for screening diseases.

One of the side-products of their operations is wastewater containing phenolic ethoxylates. Conventional water treatment methods such as UV, ozone and chemical treatment are ineffective in removing such dissolved organic pollutants from waters. As per tightening EU regulations, water that contains phenolic ethoxylates cannot be discharged to a public sewer network. Without an alternative, it has to be handled at a hazardous waste management facility.

For Wallac, this posed two challenges:

- Wastewaters containing phenolic ethoxylates had to be transported long ways

- Handling the wastewater at a hazardous waste management facility was causing high costs

For those reasons Wallac was keen to try out an alternative after they found out about Roxia’s innovative non-thermal plasma technology. The new solution presented a possible alternative to the above-mentioned conventional water treatment methods.

From lab testing to full scale

Shortly after the initial contact with Roxia, a lab test was run with a water sample from Wallac. The results were astonishing: after treatment with plasma oxidation, there were no traces of phenolic ethoxylates in the waters! With positive results from the lab, the testing was taken to full-scale, onsite unit for a few-week trial period. “Installation of the Roxia Plasma Oxidizer test equipment went through without any relevant issues. Within two weeks we had the process in full service,” says Ahonen.

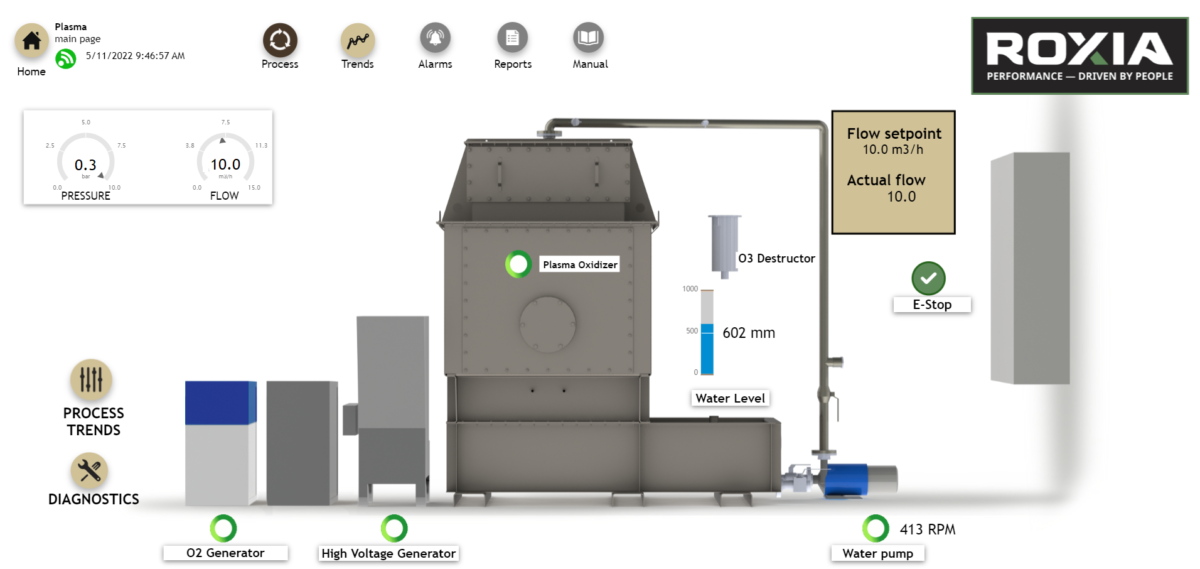

During the trial period, Roxia experts regularly collected water samples. They conducted a detailed analysis and used the results to optimise the process for maximum convenience and energy efficiency. According to Ahonen, the plasma oxidation process “works like a charm”. Wallac also has the possibility to monitor the plasma oxidation process in real time through the Roxia MalibuTM online portal.

Plasma oxidation is here to stay

With plasma oxidation removing the trouble-making substances, Wallac no longer needs to transport the challenging wastewaters a long way to hazardous waste treatment. After Roxia Plasma OxidizerTM test unit demonstrated excellent results, it was evident to Wallac that it is an impressive innovation and they chose it as their new water treatment solution.

As for whether Wallac would choose the same product again, Ahonen’s answer is a clear yes: ”I would recommend this product to any process where harmful substances need to be removed from waste solutions before discharge to sewer. Roxia’s technology enables us to meet EU emission limits for e.g. production operations where Triton X-100 is used.”

Roxia Plasma OxidizerTM

Roxia Plasma Oxidizer is effective and chemical-free non-thermal plasma technology for industrial water purification. Plasma generated oxidants in direct contact with water effectively remove color, odor and organic residues while disinfecting the water. Roxia Plasma Oxidizer (RPO) is a trailblazing water purification system alternative to ozone, UV and chemical treatment.