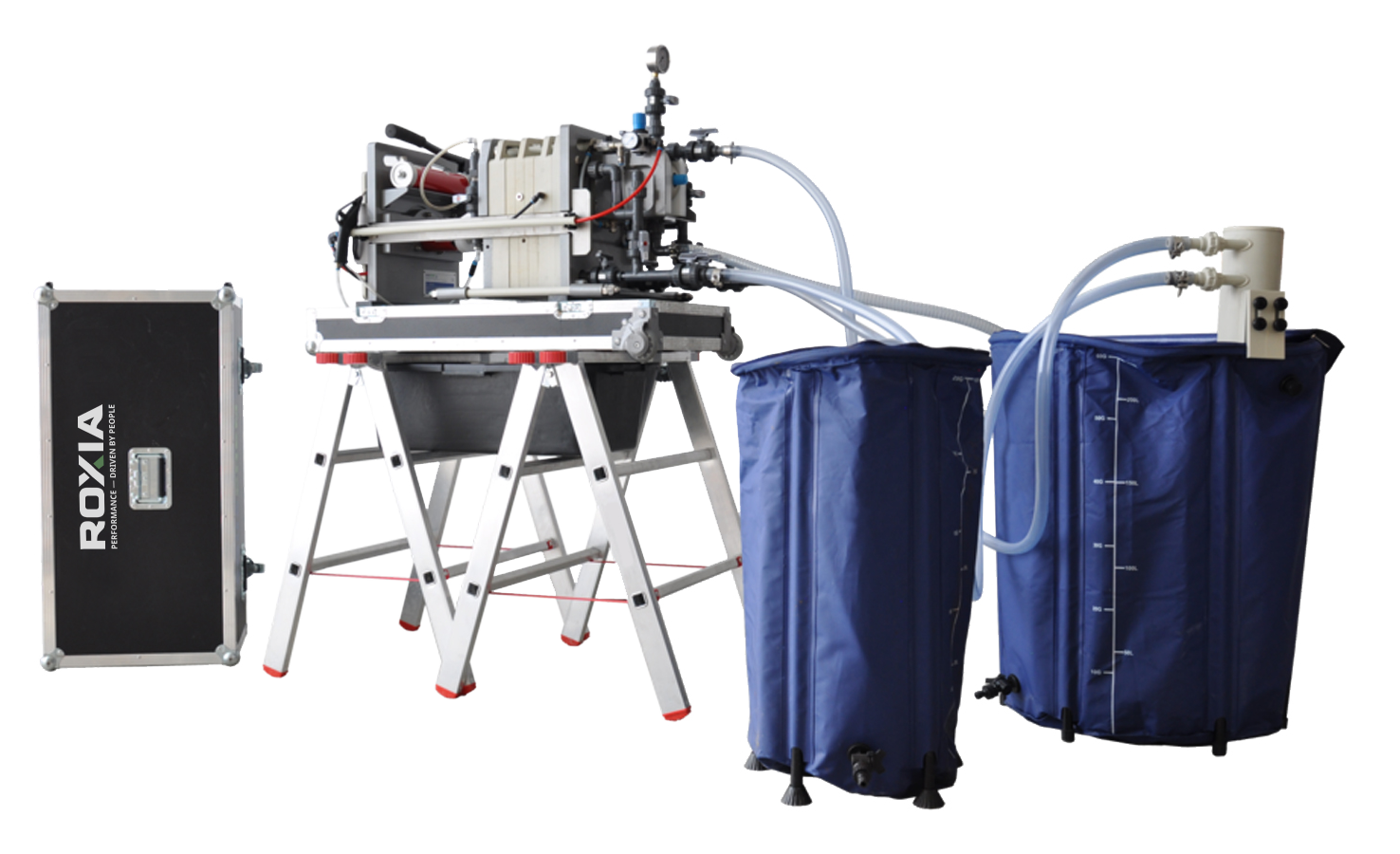

Pilot scale mobile testing filter press with accessoriesSmart Filter Press 470 Pilot Unit

Included in the scope of supply:

-

- filter press SFP470 Mini AM32-4-16

- fully installed on rollers

- chamber volume: 16 litres

- filtration surface: 1.28m²

- with control system and touch display

- sludge trolley

- DN 25 filtrate drainage hose

- filter press dimensions with opened cover: 260 x 150 x 170cm

- weight: approx 1.2t

To be supplied by the customer:

-

- pneumatic connection: 1/2″ inner thread with quick-release coupling

- power connection: 230 V / socket

- customer’s pump connection 1″

- filtrate drainage: DN 32 hose