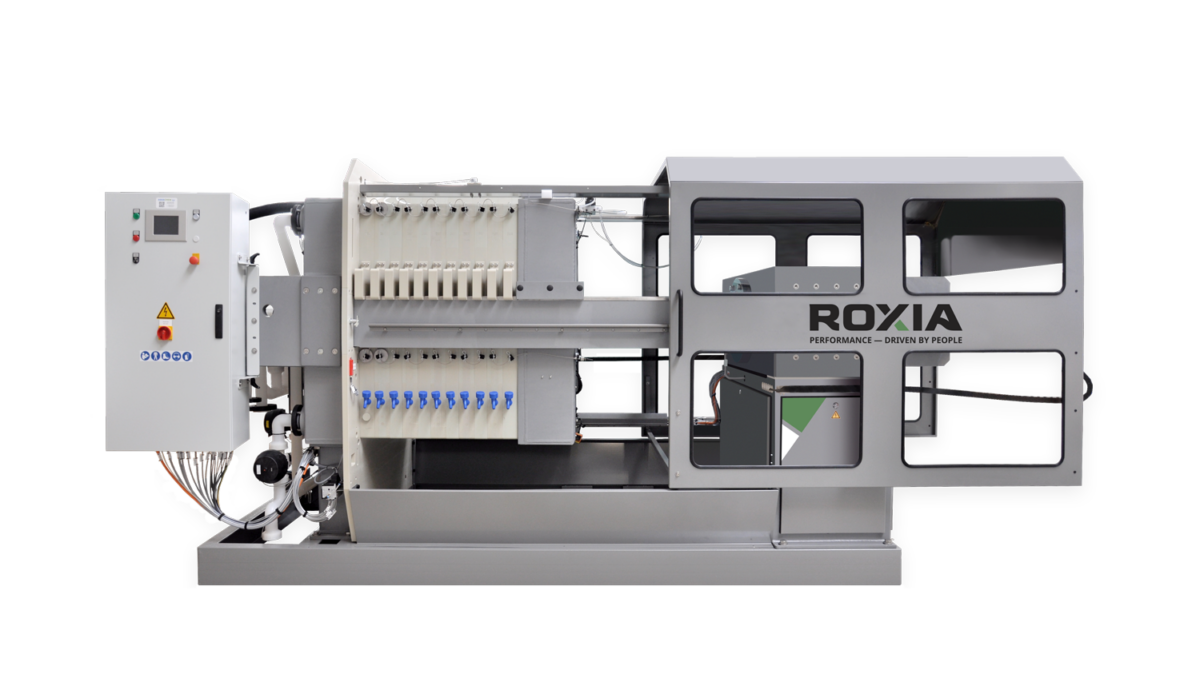

The Roxia Smart Filter Press™ (SFP) is revolutionising the filtration industry with a capacity up to ten times higher than traditional recessed filter presses of similar size. This advanced system offers fully automated operations, enhanced safety, and significant reductions in operational costs.

Key Benefits of Roxia Smart Filter Press™

- Fully Automatic Operation and Enhanced Safety

The Roxia Smart Filter Press™ boasts complete automation of all operational stages, resulting in high unmanned availability of over 98%, with only periodic inspections required. The system is equipped with multiple error detection functions that enhance safety and performance. Additionally, there is an option to integrate the filter press with the Roxia Malibu™ online portal for remote monitoring and performance analysis, further increasing operational efficiency and oversight.

- Clean and Safe Operation

Safety and cleanliness are at the forefront of the Roxia Smart Filter Press™ design. It features gasketed filter plates and enclosed, interlocked doors that prevent slurry sprays and minimise human contact with filter cakes or fumes. The design eliminates the need for operator involvement near moving parts. Each filtration cycle includes a self-diagnostic feature with leak-testing to ensure the filter remains clean, even in traditionally dirty applications.

- Low Maintenance and Environmental Impact

The Roxia Smart Filter Press™ is designed to minimise maintenance needs and environmental impact. Its optimised process cycle reduces the consumption of utilities and the requirement for wear and spare parts. An advanced washing system extends the life of filter cloths, while automated failure analysis supports preventive maintenance. Enhanced diagnostics and remote support capabilities facilitate troubleshooting, ensuring the filter press operates smoothly with minimal downtime.

Applications of Roxia Smart Filter Press™

The versatility of the Roxia Smart Filter Press™ makes it suitable for various applications, including flue gas desulphurisation (incinerators), process water recycling in metal finishing, electrochemical machining (ECM), concrete industries, industrial effluent treatment, and municipal sludge dewatering.

Technical Specifications

| Model | Filtration Area (m²) | Plate Format (mm) | Number of Chambers | Filter Volume (l) |

| SFP 470 1 GM32 | 1.28 | 470 x 470 | 4 | 16 |

| SFP 470 3 GM32 | 3 | 470 x 470 | 10 | 40 |

| SFP 630 6 GM32 | 5.9 | 630 x 630 | 10 | 86 |

| SFP 800 10 GM32 | 9.9 | 800 x 800 | 10 | 154 |

| SFP 1000 15 GM32 | 14.9 | 1000 x 1000 | 10 | 238 |

| SFP 1200 22 GM32 | 22.3 | 1200 x 1200 | 10 | 365 |

Enhance Process with Smart Filtration

Roxia Malibu™ Online Portal

The Roxia Smart Filter Press™ can be connected to the Roxia Malibu™ online portal for remote monitoring and performance analysis. This integration allows operators to optimise the filtration process, increase production volume, and detect failures before they occur. All these functions can be managed from any internet-connected device, enabling operators to maintain control and oversight from virtually anywhere.

Comprehensive Filtration Solutions by Roxia

Roxia offers extensive expertise and support in filtration technology, ensuring that each Smart Filter Press™ as every Roxia filter solution, is tailored to meet specific needs. This support includes detailed process analysis and filtration testing, tailored sizing based on test results and practical experience, optimisation of filtration cycles and performance, and maximisation of filtration process output. Roxia also provides guidance on the selection and sizing of auxiliary equipment and offers continuous service support throughout the filter’s lifecycle.

By leveraging these advanced features and comprehensive support services, the Roxia Smart Filter Press™ stands as a cutting-edge solution in modern filtration technology. This next-generation filter press not only enhances operational efficiency but also significantly reduces maintenance costs and environmental impact. For more information on how Roxia Smart Filter Press™ can transform your filtration processes, contact us.