Electrochemical Machining (ECM) finds its application in various industries, including aerospace, medical technology, automotive, and energy generation. ECM enables companies to machine components with high precision and excellent surface finish, making it ideal for the manufacture of engine components, medical devices, vehicle parts and energy systems.

ECM – What Is It Exactly?

Electrochemical machining (ECM) is a method of metal removal through an electrochemical process. It is primarily used for mass production and machining extremely hard materials or those difficult to machine using conventional methods. ECM is limited to electrically conductive materials.

This specialized manufacturing process relies on electrochemical reactions to precisely machine metallic workpieces. Unlike conventional mechanical machining processes such as milling or grinding, ECM removes material through targeted electrochemical reactions rather than mechanical forces.1 The advantage of ECM lies in its ability to produce highly precise and complex shapes with excellent surface quality, without causing mechanical stresses or deformations in the workpiece.

What Exactly Happens, and What Role Do Filter Presses Play?

The basic principle of ECM involves an electric current flowing between the workpiece to be processed (anode) and a special electrode serving as a tool (cathode). The charge transport in the machining gap is facilitated by an electrolyte solution, an aqueous solution of sodium chloride (NaCl, saline solution) or sodium nitrate (NaNO3). The resulting flow of electrons dissolves metal ions from the workpiece. The dissolved metal ions then undergo reactions with parts of the split electrolyte at the anode, while at the cathode, the electrolyte residue reacts with water. The electrolyte can be processed by filter presses to separate the metal hydroxides from the electrolyte solution. The end product is metal hydroxide, which settles as sludge and must be removed. The resulting sludge is further dewatered with filter presses before being disposed of as hazardous waste.[2]

Application Examples for Filter Presses in ECM

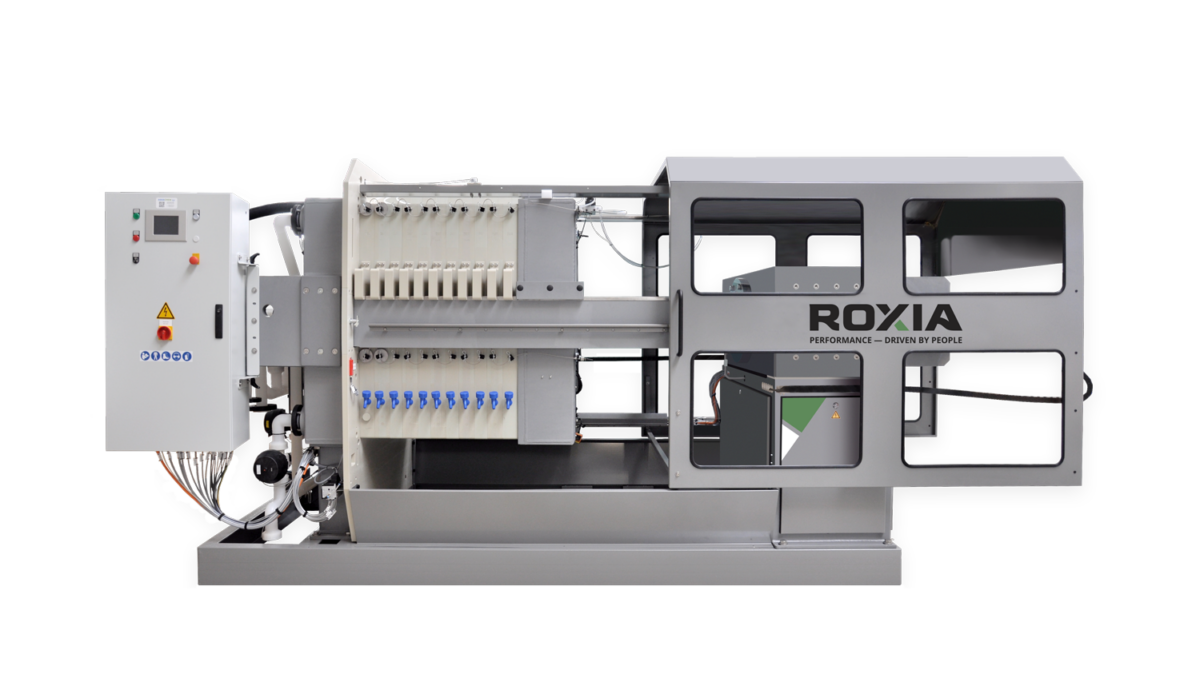

Over the years, we have collaborated with many companies where our filter presses have found application in ECM. One such example is this AQUACHEM project in the aerospace industry, where precision is crucial in the manufacturing of individual aircraft components. Our filter presses enable manufacturers to meet the highest quality standards while ensuring efficient and sustainable production processes, particularly for exotic materials with high requirements in terms of crack-free and surface quality.

Do you work in the field of surface treatment, and you would like to find out more about our solutions?

We will be happy to assist you. Click here to find your nearest contact.

Sources:

1. Manufacturing Processes 3. VDI Book. Springer, Berlin, Heidelberg