Processes & Technologies

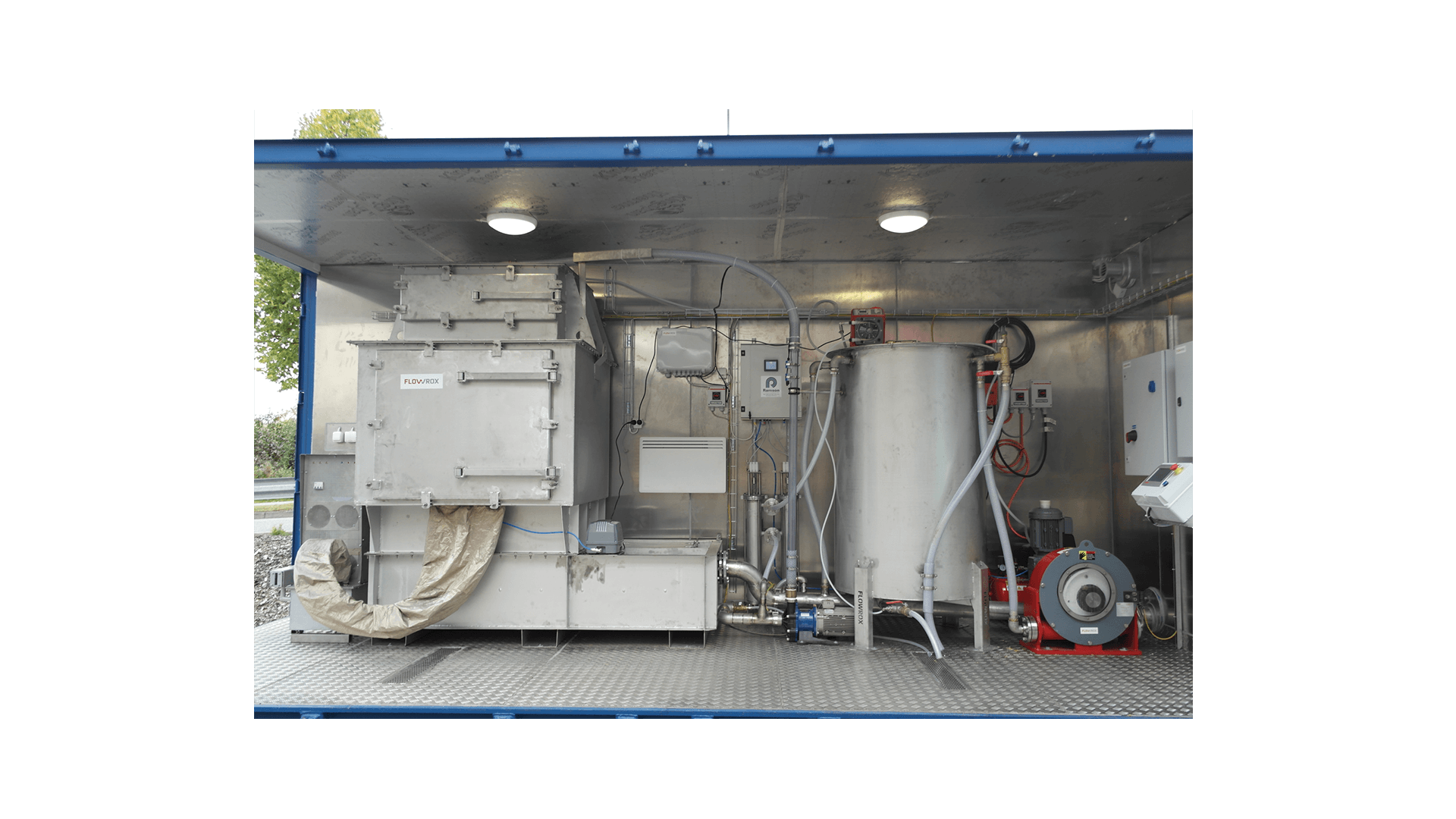

Water treatment nearly always requires a multi-step process combining several unit operations. We apply the best available techniques and find the most feasible combination to each case. Such techniques typically include chemical treatment like pH control, coagulation and flocculation; flotation, settling or other solid-liquid separation processes like filtration; aeration or advanced oxidation etc. Roxia also develops completely new technologies for water treatment. As our water treatment flag ship, check out the world’s first direct plasma oxidation system: Roxia Plasma Oxidizer

Studies of the wastewater are done by Roxia experts with a variety of technologies and processes.